Meet Multistation at AM Village 2024 | 13 -17 May | Tournai, Belgium

Booth E117 Hall 4 - Le Bourget - Paris - France - Du 19.06 au 23.06

The 54th edition of the Show will take place at the Le Bourget Parc des Expositions in June 2023, and once again will bring together all the players in this global industry around the latest technological innovations. The first four days of the Show will be reserved for trade visitors, followed by three days open to the general public.

Multistation provides the aerospace industry, whether they are engine or aerostructure manufacturers. Highly sophisticated machining centers, automatic riveting machines, milling machines… Multistation offers a complete range of products by presenting 4 stakeholder :

The 5 axis machining center HSTM with horizontal component orientation is particularly suitable for the machining of turbine and compressor blades, blisks/impellers and/or radial compressor fans. The slide-ways have been inclined at an angle of 45° to the front to ensure an optimum mass distribution, excellent loading possibilities and an excellent view of the working area. Where the attainable accuracies and surface qualities are concerned, the HSTM even exceeds the highest demands for modern blade machining. Continuous maximum productivity is ensured by its sturdiness and rigidity, as well as by the integration of an HSC-support

What is a Hybrid machine?

A Hybrid machine is one where you can change between manufacturing processes as easily as you change between milling cutters. Hybrid machines mix technologies together to allow processes to be combined, as required. The ability to extend end-of-life of high value, complex components made from specialized materials, is both cost effective and environmentally friendly.

Don’t just load your machine with milling cutters; load it full of adaptive processes: High Speed Milling + 3D Scanning + Laser Cladding + 3D Inspection + Deburring / Polishing + Laser Marking… all in a single machine !

Meltio offers an innovative 3D metal printer that deposits laser-melted wire on a Cartesian 3-axis system, all within a closed enclosure, guaranteeing a controlled and secure environment during the printing process. This technology makes it possible to create complex metal parts with high precision and quality.

Meltio stands out for its ease of use, proven reliability and portability, making it an ideal choice for the manufacture of metal parts and spare parts in a variety of environments.

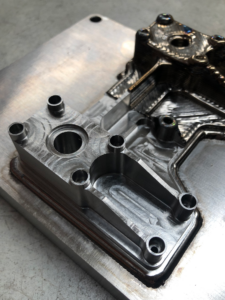

Prima Additive’s machine is specially designed to meet high-precision, high-quality additive manufacturing requirements for a variety of copper applications. PBF (Power Bed Fusion) or SLM (Selective Laser Melting) processes use a bed of finely selected copper powder as the base material, which is then melted using a high-power laser.

Thanks to its multi-process robot cell and range of laser sources, it offers exceptional versatility for applications such as wire deposition, laser welding and heat treatment. This machine is designed to help industries fully exploit the advantages of additive manufacturing in the production of high-precision, high-quality copper parts.

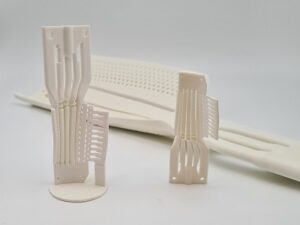

Admatec offers 3D printers based on the DLP (Digital Light Processing) process, an advanced technology that enables the creation of highly precise parts with printed walls down to 100 μm. These printers use a mixture of powders and light-sensitive resins, such as zirconia, alumina, silica, hydroxyapatite and even metals. Once printing is complete, the part undergoes a debinding process to remove residues of unpolymerized resin. It then goes through a sintering process, which involves heating the part to a high temperature to fuse the material particles together, ensuring optimum strength and stability.

One of the great strengths of Admatec printers is their ability to produce highly accurate parts, with fine detail and tight tolerances. The resolution of the projected image enables high dimensional accuracy, which is essential for applications requiring high quality, such as the manufacture of dental prostheses, medical implants, parts for the aerospace industry, etc.

For more information, to request a meeting or to receive an offer with our financing proposals, send your request to multistation@multistation.com or call +33 2 99 163 535