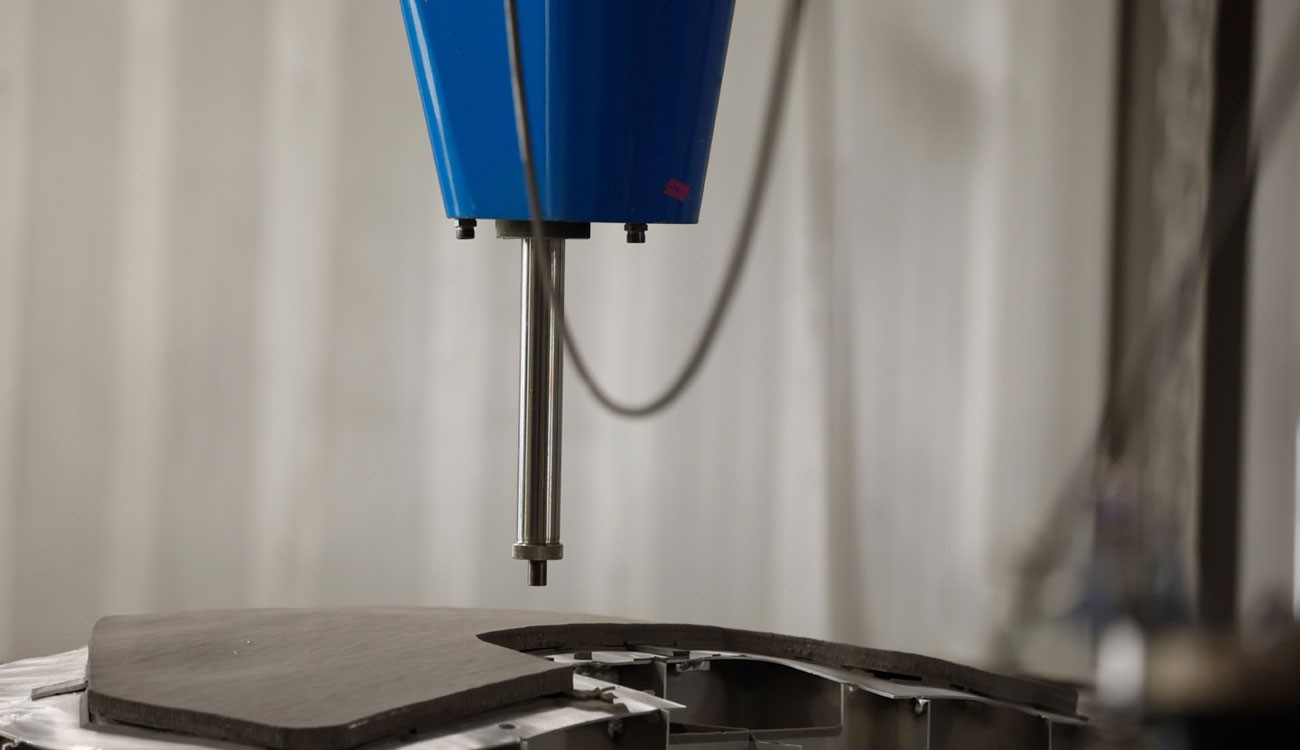

TITOMIC TKF 9000 : Coldspray Technology

Suitable for industrial production

A large manufacturing volume of 40.5 m3 allows a wide variety of parts to be produced in an automated process. The user interface is designed to be easy to use.

This solution is customizable according to the customer’s needs.

A unique combination of materials

The coldspray technology allows to use dissimilar alloys simultaneously (Titanium and Copper for example) and to fuse them by kinetic energy to obtain a unique alloy.

FR

FR