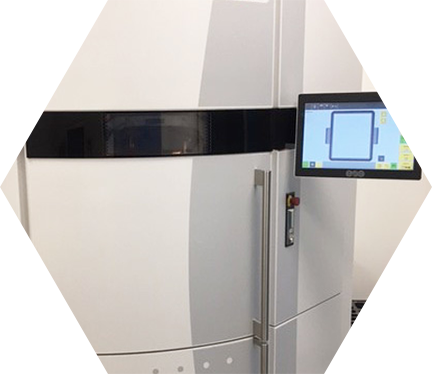

STRATASYS FORTUS 450MC plus

- YOM: 2017

- Nbr of hours: 2 213 h

- Soft version: 6.2.6624.0

- Materials:

- ABS-ESD7 / ABS-M30/ ABS-M30i

- ASA

- Nylon 12

- PC-ABS / PC-ISO / PC

- ULTEM1010 / ULTEM1010 CG / ULTEM9085 / ULTEM 9085 CG

Reference: M220402F

High-performance thermoplastics for specialized production parts in demanding fields such as medical, aerospace, research and defense.

No responsibility whatsoever is assumed with respect to technical description, quality, dimensions, year of manufacturing and completeness of machines.

The descriptions are made under full reserve of potential errors which will be without any influence on a concluded sale

Reference: M220402F

Materials :

ABS-ESD7

ABS-M30

ABS-M30i

ASA

Nylon 12

PC-ABS

PC-ISO

PC

ULTEM1010

ULTEM1010 CG

ULTEM9085

ULTEM 9085 CG

Type/Model : 450 MC

YOM : 2017

Process : FDM (Fused deposition modeling)

Condition : Good condition

Sell your machine in a few clicks with our exclusive and confidential second hand marketplace

Sell your machine

Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.

Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.

Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet.