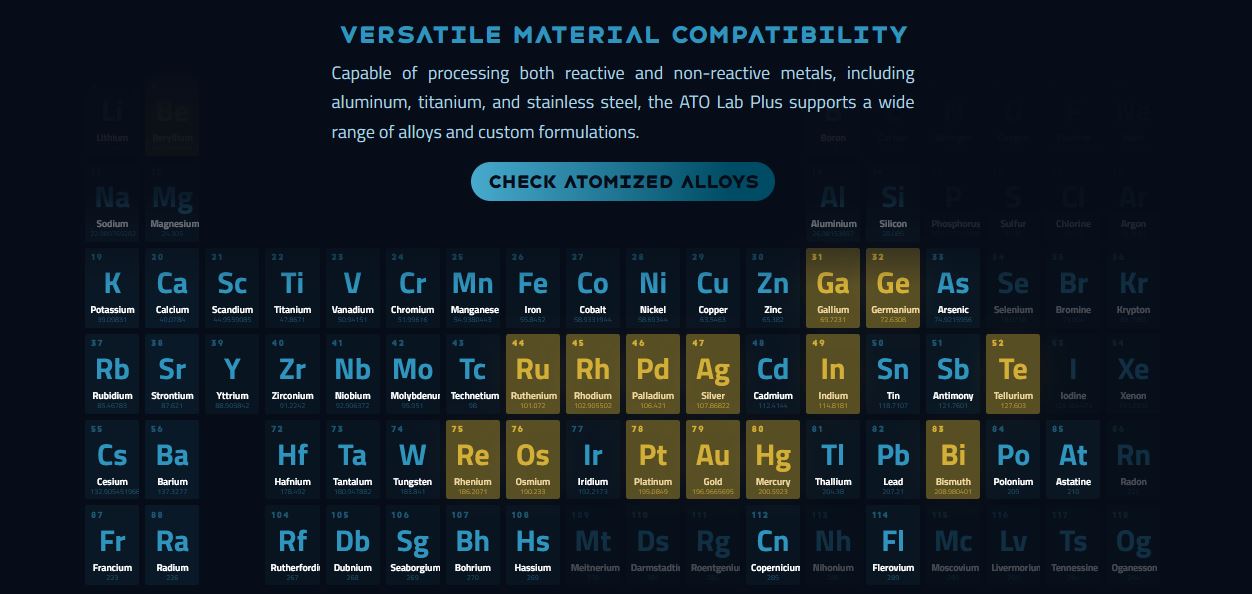

3D Lab – ATO Sparq

New ATO Sparq enables you to make metal powder

yourself by optimizing the production of both

reactive and non-reactive powders on a smaller,

self-sufficient scale – now with AI-ready control.

Innovate alloy formulations, experiment with

various metals and their alloys, and let built-in

image analysis and AI guidance help you keep the

process in the optimal window

Open a new chapter in your research and development with ATO Sparq.

Design your alloy and quickly produce spherical metal powder with high flowability,

perfect for your Additive Manufacturing and powder metallurgy needs

– with the machine actively “watching” and tuning the process.

ATO Sparq throughput reaches several hundred grams of metal powder per hour

with a particle size from 20 to 120 μm.

Additionally, depending on selected ultrasonic ATO Frequency System module,

it’s possible to produce a specific Particle Size Distribution tailored to user needs.

KEY FEATURES

- AI-ready atomization control

- Highest powder quality

- Compact lab-scale design

- Wide alloy compatibility

- Modular, expandable system

- TIG + Plasma melting

- Quick material change

- Large powder container with fill monitoring

- High safety and stability

- Cost-efficient and scalable

The quality of the software is a strong factor for the user’s experience.

We know this, so we’ve given ATO Sparq an intelligent,

AI-ready control system that’s adaptable and easy to use

Users manage the process through a dual touchscreen and precise controls,

while AI assists in maintaining optimal atomization conditions.

The interface allows quick adjustment of ultrasonic and melting parameters

and enables remote monitoring and control of the entire process

ATO Sparq comes with a vacuum pump, which quickly

creates the right environment with very low oxygen levels.

This ensures the materials are of the highest chemical purity.

Thanks to its tight-sealing chamber, it can make powders of

reactive metals and their mixtures, like titanium and

aluminum, and monitor the process via two independent

camera views. The upgraded industrial computer, ambient

lighting and tray under the process chamber improve

ergonomics and visibility, while built-in diagnostics watch

the condition of consumables and notify the operator when

maintenance is needed.

ATO Sparq boosts productivity by oering exible congurations.

Users can choose from several feeding system modules, each

designed for specic input materials:

Additionally, custom feeders can be provided upon request.

traditional atomization limitations and bring AI into the heart of the process.

ATO Sparq has a compact form, making it possible for comfortable usage even

in a limited space, now enriched with ambient interior lighting and an ergonomic

tray under the process chamber.

Along with its innovative technology, integrated AI tools and no requirements

for sophisticated infrastructure, it ensures exceptionally low operating costs,

high stability and a quick return on investment.

high-end atomization in your laboratory

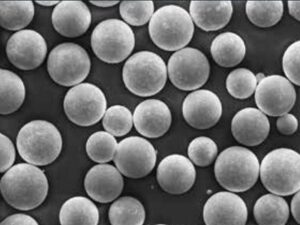

Unsieved, raw ATO sparq plus powder, note the uniform size and spherical shape of the particles.

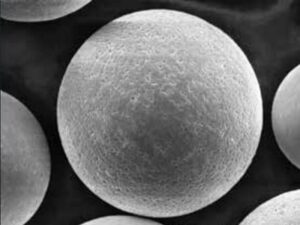

A spherical IN718 powder particle produced in ATO Lab aprq

FR

FR