KS-JT KSS1800B – Industrial High-Precision 3D Sand Printer

Performance, flexibility and productivity for digital foundry production

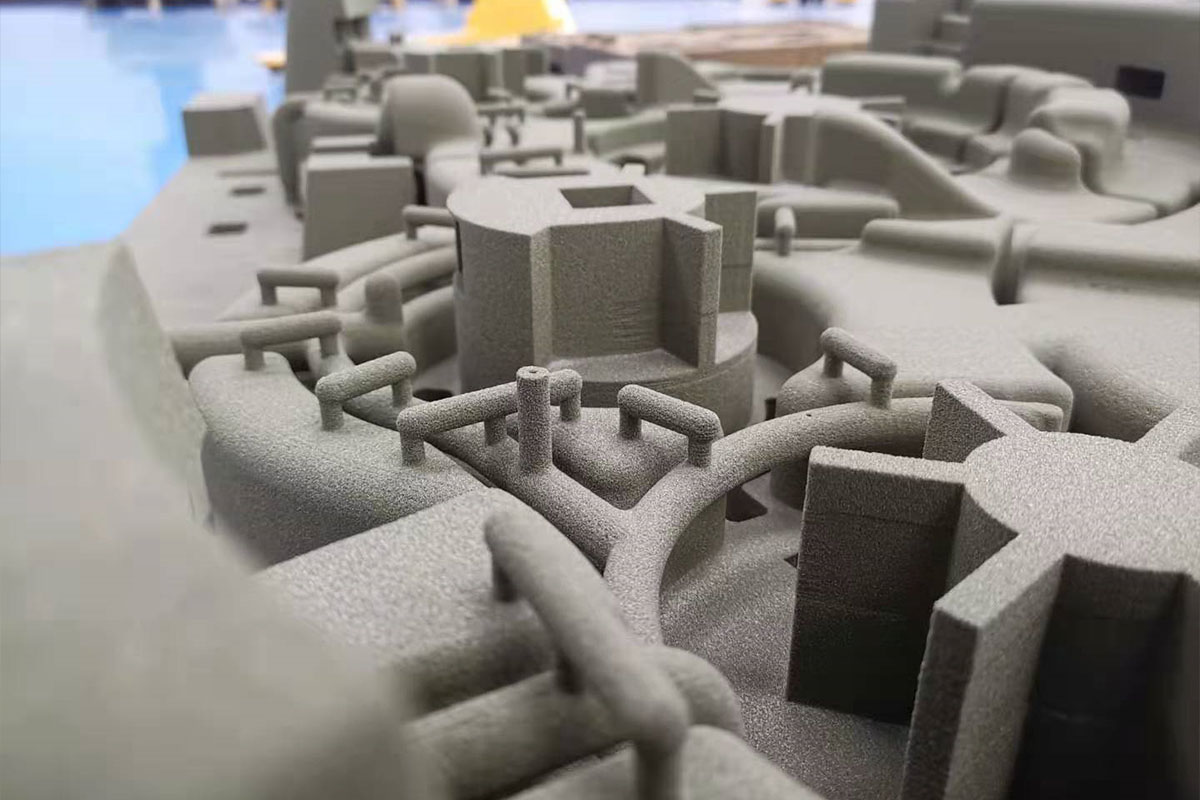

The KSS1800B from KS-JT is a high-performance industrial 3D sand printer designed for large-scale production of molds and cores for metal casting.

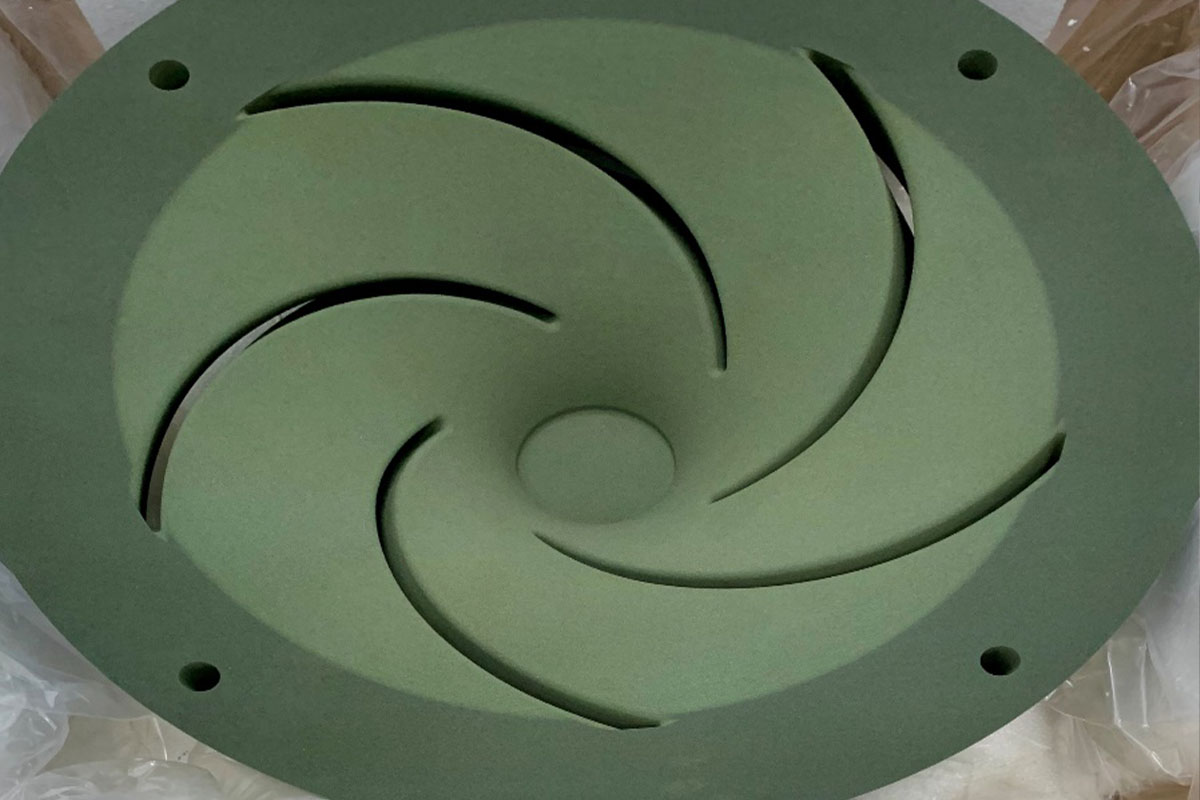

With its bidirectional sand-laying technology and 400 DPI printing resolution, it delivers highly accurate molds up to CT7 precision, while achieving outstanding throughput of up to 270 L/h.

Compact, modular, and fully compatible with automated production lines, the KSS1800B is the ideal solution for foundries seeking high productivity and process digitalization.

Product Description

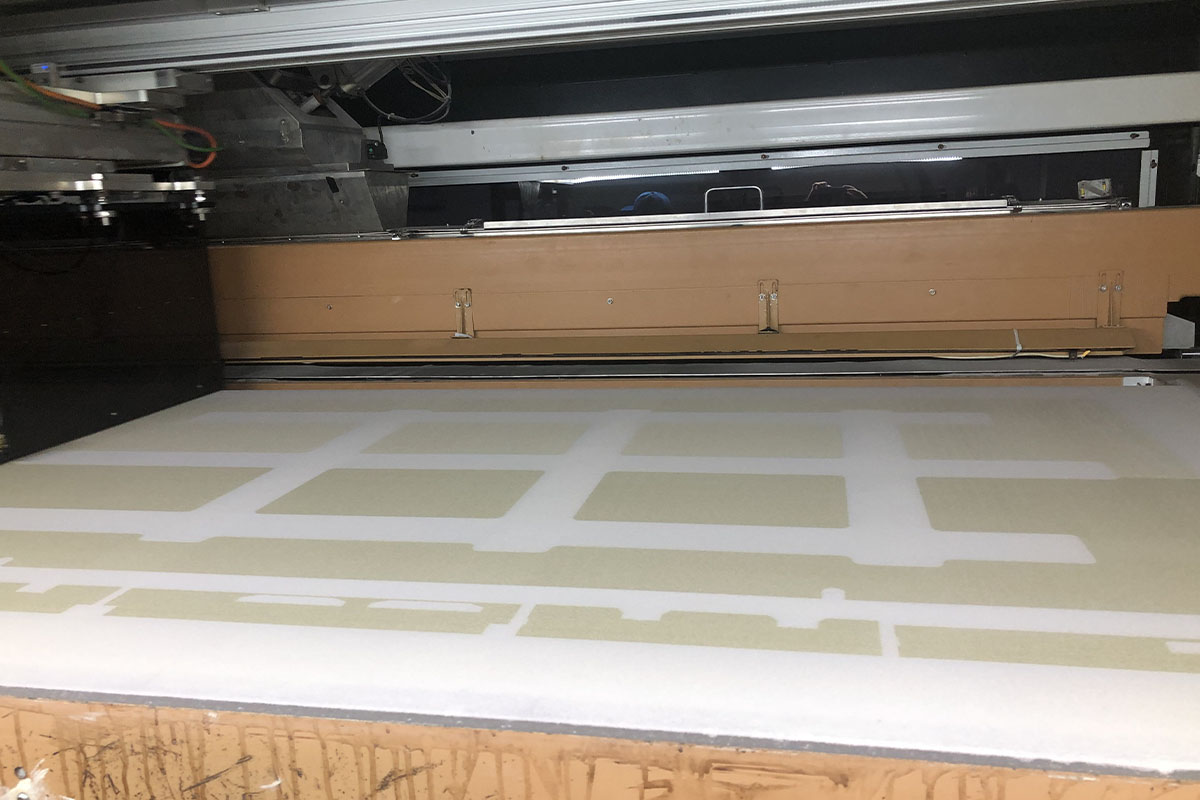

The KSS1800B uses binder jetting technology with furan or phenolic resins to manufacture complex sand molds from digital CAD models directly — eliminating the need for traditional tooling.

Its removable job box streamlines workflow and enables seamless integration into automated production lines.

With a large build volume of 1800 × 1000 × 700 mm, the machine is perfectly suited for large molds, multi-part batches, and high-value castings.

The system’s bidirectional sand-laying and 8-module printhead assembly (1024 nozzles per head) ensure efficient printing, reaching speeds of up to 1200 mm/s.

Key Advantages

- High precision: 400 DPI resolution and CT7 accuracy for fine and consistent sand molds.

- High productivity: Sand-laying up to 400 mm/s and printing efficiency up to 270 L/h.

- Large industrial format: 1.8 × 1.0 × 0.7 m job box for large castings.

- Flexible workflow: Removable job box for direct transfer to coating, assembly, and casting.

- Compact footprint: Only 9.7 m², reducing installation space.

- Low noise: Operates below 60 dB, suitable for industrial environments.

- Automated production: Compatible with online multi-machine industrial setups and automated sand-processing systems.

- Software-friendly: Works with standard CAD tools such as SolidWorks, UG, and ProE.

FR

FR