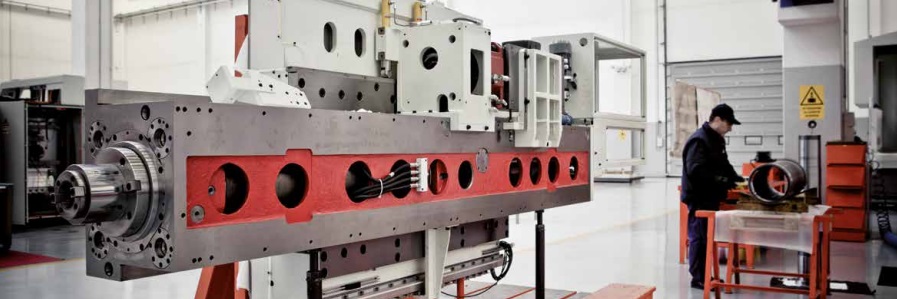

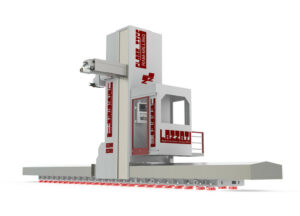

Hydrostatic Moving Column Machines

RAM-MILLING

RAM-MILLING

- Head with Milling Borer RAM movement,

- travel 1500 x 2000 mm,

- equipped with universal controlled head 360°.

ADvantages

- No more limits for the customer’s personalization and customization.

- High Rigidity and Precision for the Built-In design.

- Possibility to have different heads on.

- High flexibility and availability of the machine.

- Easy maintenance and quick troubles shooting.

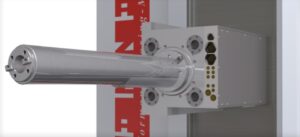

RAM-BORING

RAM-BORING

- Head with Milling Borer RAM movement,

- travels 1.000 x 1.600 mm

- and boring spindle movement Ø130 ÷ 200 mm,

- travel 800 x 1.100 mm,

- equipped with interface for accessory heads.

Advantages

Modern Project

- High Rigidity of the structures

- Ergonomically Designed

- Safety Integrated System

High Precision Machine

- LHS – All Hydrostatic Guideways

- TCS – Constant Control of the Temperature

- DCS – Dynamic Compensation System of the Mobile Headstock falling

- Big Bearings dimension on the Headstock for the Spindle

- Guaranteed High Precision on Machine Positioning and Geometry

Max. Universality

- LTS – LAZZATI Twin System which allows no stop working

- Boring and Milling in one Machine

- Possibility of customized configuration

- Ample choice of Accessories and Personalization

- Maximum Flexibility and Convenience in the positioning of whatever pieces

FR

FR

RAM-MILLING

RAM-MILLING RAM-BORING

RAM-BORING Ram Boring

Ram Boring Ram Milling

Ram Milling