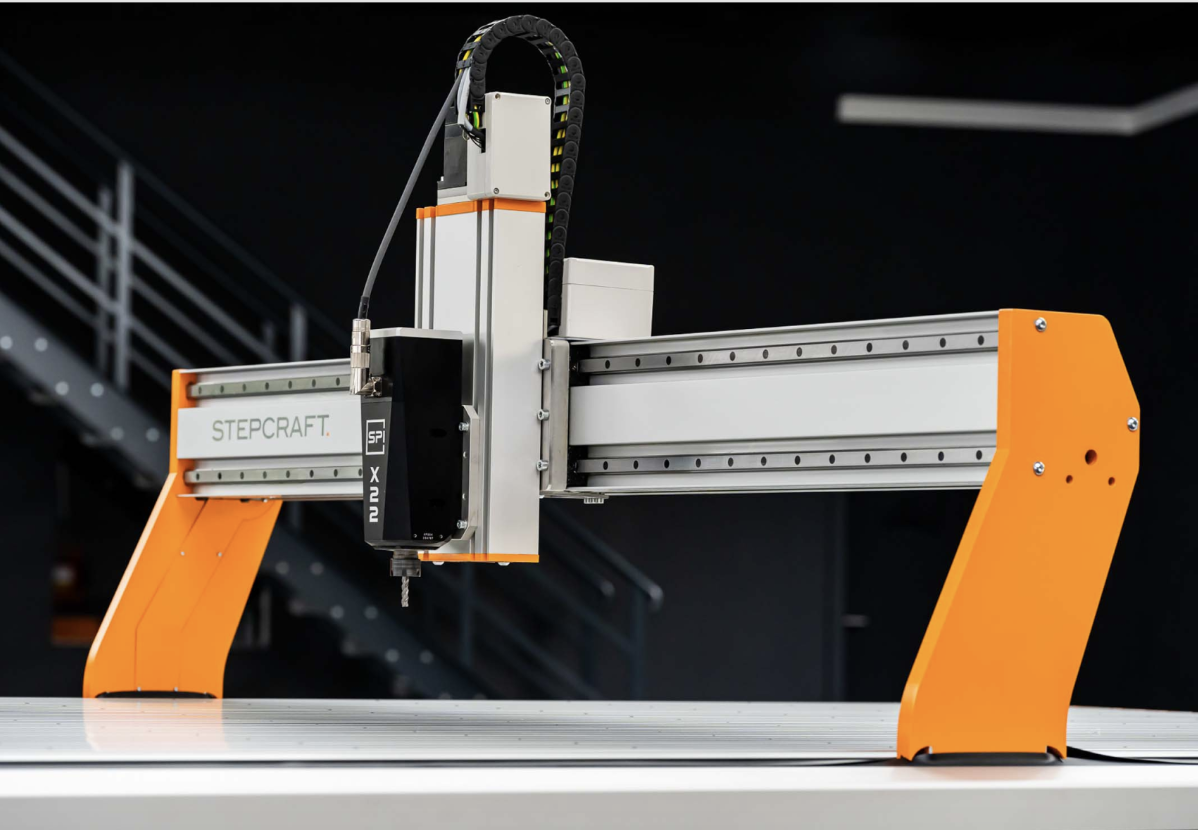

Stepcraft Q 408

Design and components

Structure: reinforced frame with 10 cross-beams, 12 junction plates and 6 integrated feet for maximum rigidity

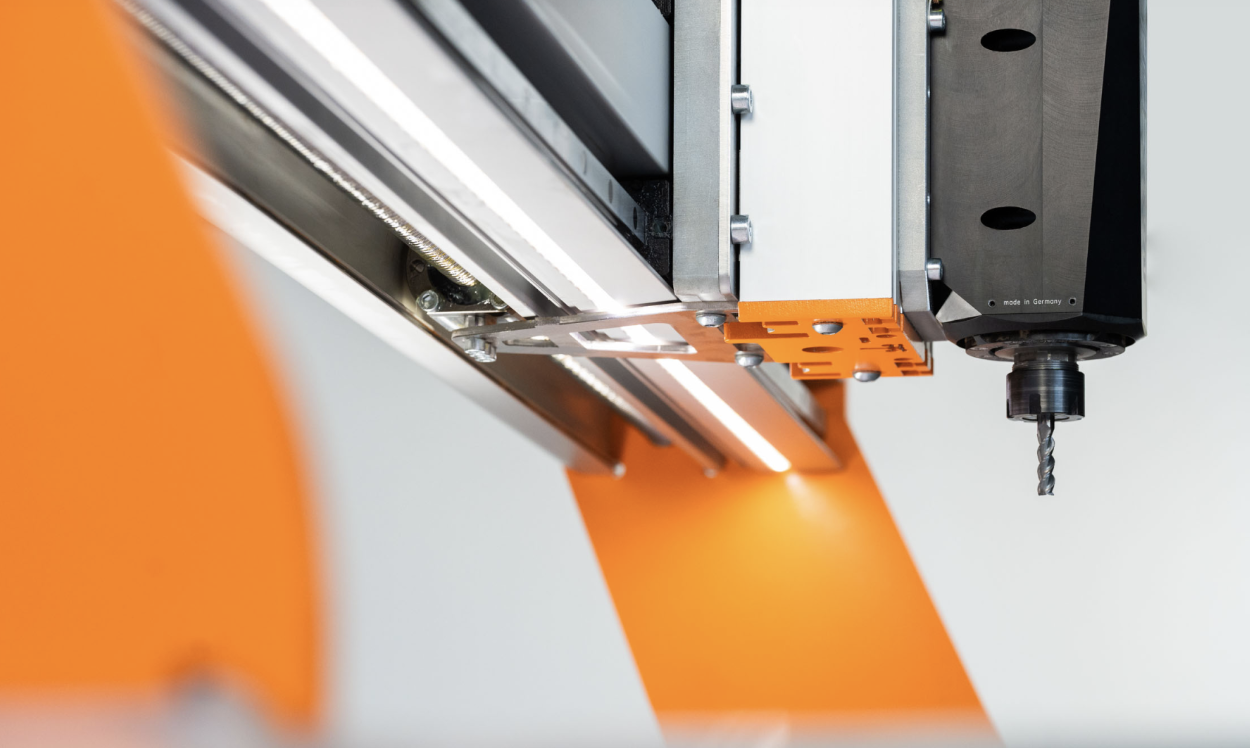

Components: high-strength aluminium, 20 mm linear guides and 20 mm thick aluminium side panels Cabling system: IGUS cable chains for increased durability

Chip management

The Stepcraft Q.408 chip extraction system is designed to maintain a clean and safe working environment, ensuring efficient extraction of dust and debris generated during machining.

These shoes are designed to maintain constant contact with the surface of the material, regardless of the movement of the Z axis, ensuring optimum dust collection.

Equipment and options

Pneumatic pin system: for fast, accurate part positioning

Automatic tool changer: 7 HP spindle with 10 tools, ISO30 cone and ER32 collets

Integrated tool contact sensor: for automatic tool configuration

Vacuum table: for optimum clamping of workpieces

Laser sight

The Stepcraft Q.408 incorporates a crosshair laser for precise positioning of workpieces and defini

tion of the machining zero point. This feature is particularly useful for quick alignments and set-ups at the start of a job, reducing set-up time and improving productivity. Applications The Q.408 is ideal for joinery workshops, panel manufacturers, prototyping workshops, sign makers and mass production where high accuracy and reliability are required.

FR

FR