3D Lab – ATO Lab (V2026)

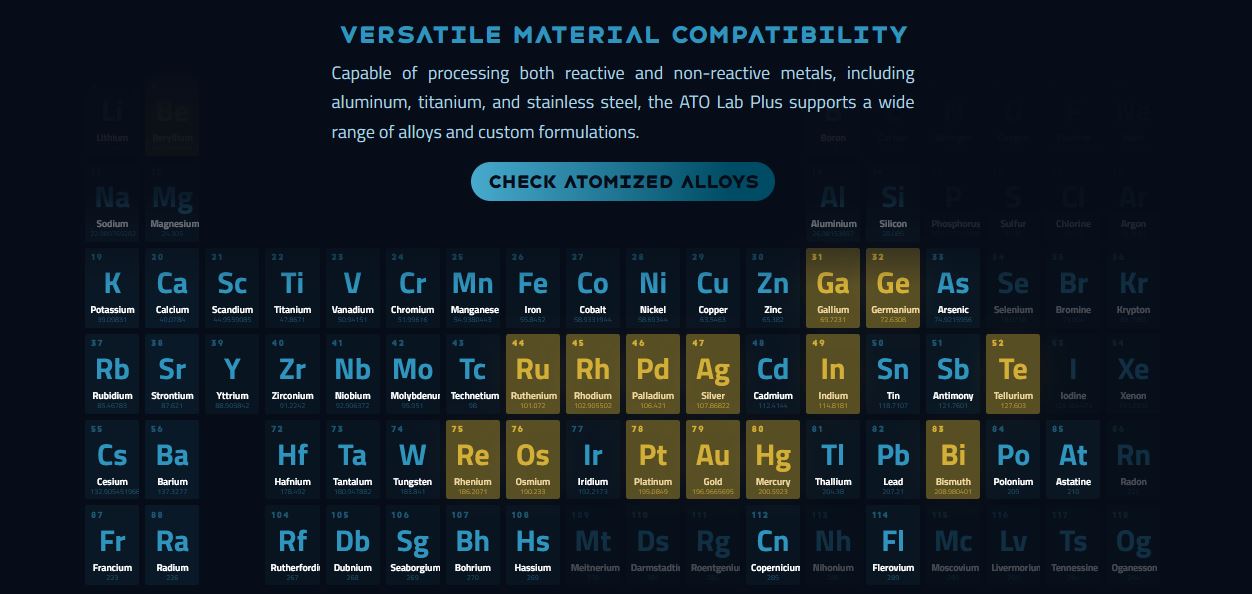

The ATO Lab is a metal spherical powder manufacturing machine for Powder 3D printing machines and powder metallurgy. A compact machine that allows to work on all types of metals (reactive or not). With a vacuum pump and the current gas treatment (oxygen, argon), the machine can obtain the best purity degree possible.

These machine can be used to launch batches in small quantities.

high-end atomization in your laboratory

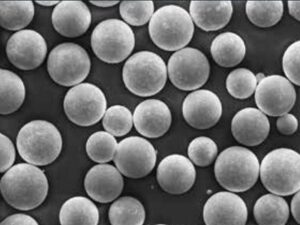

Unsieved, raw ATO Lab plus powder, note the uniform size and spherical shape of the particles.

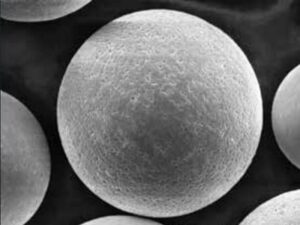

A spherical IN718 powder particle produced in ATO Lab plus

FR

FR