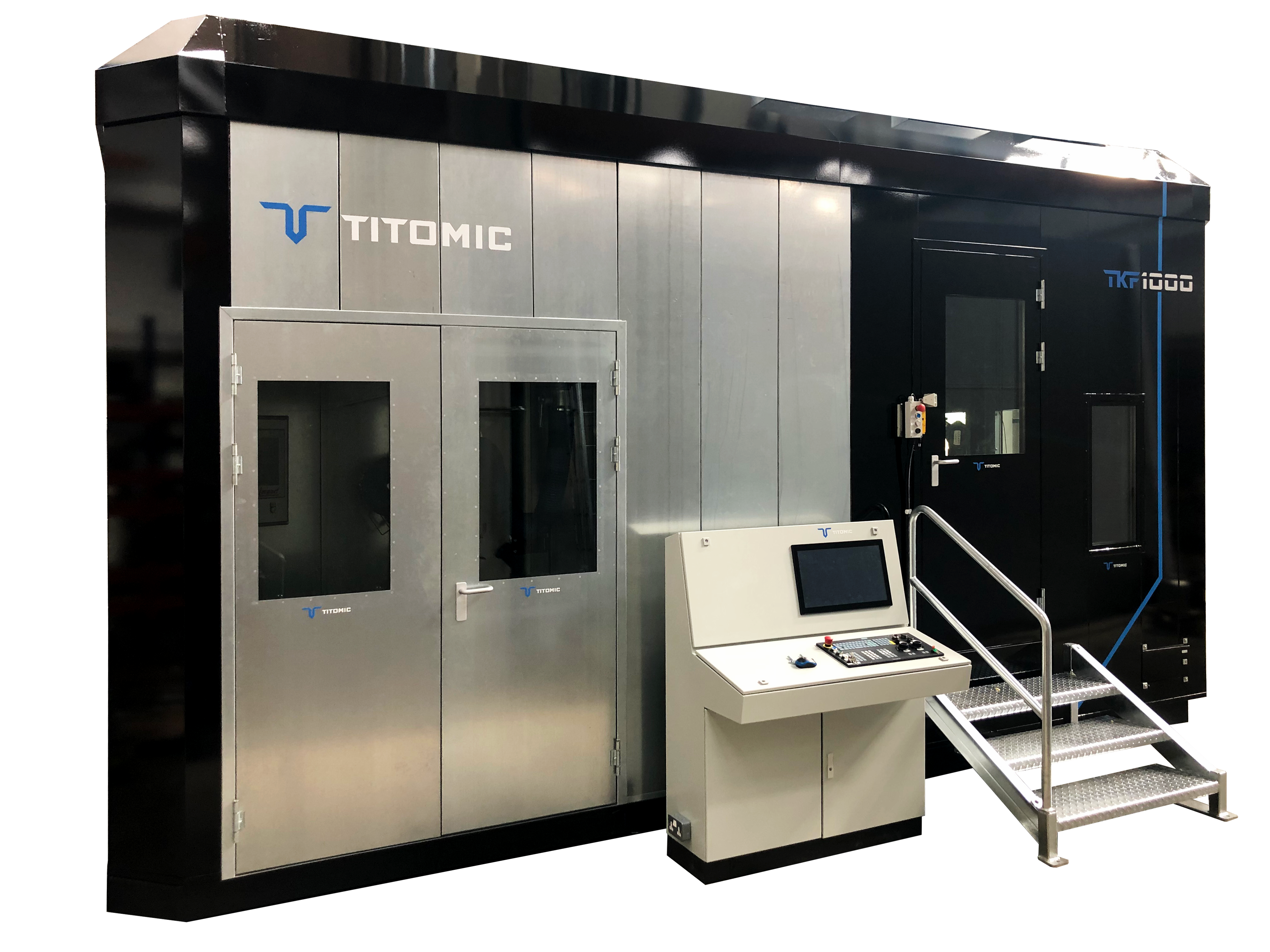

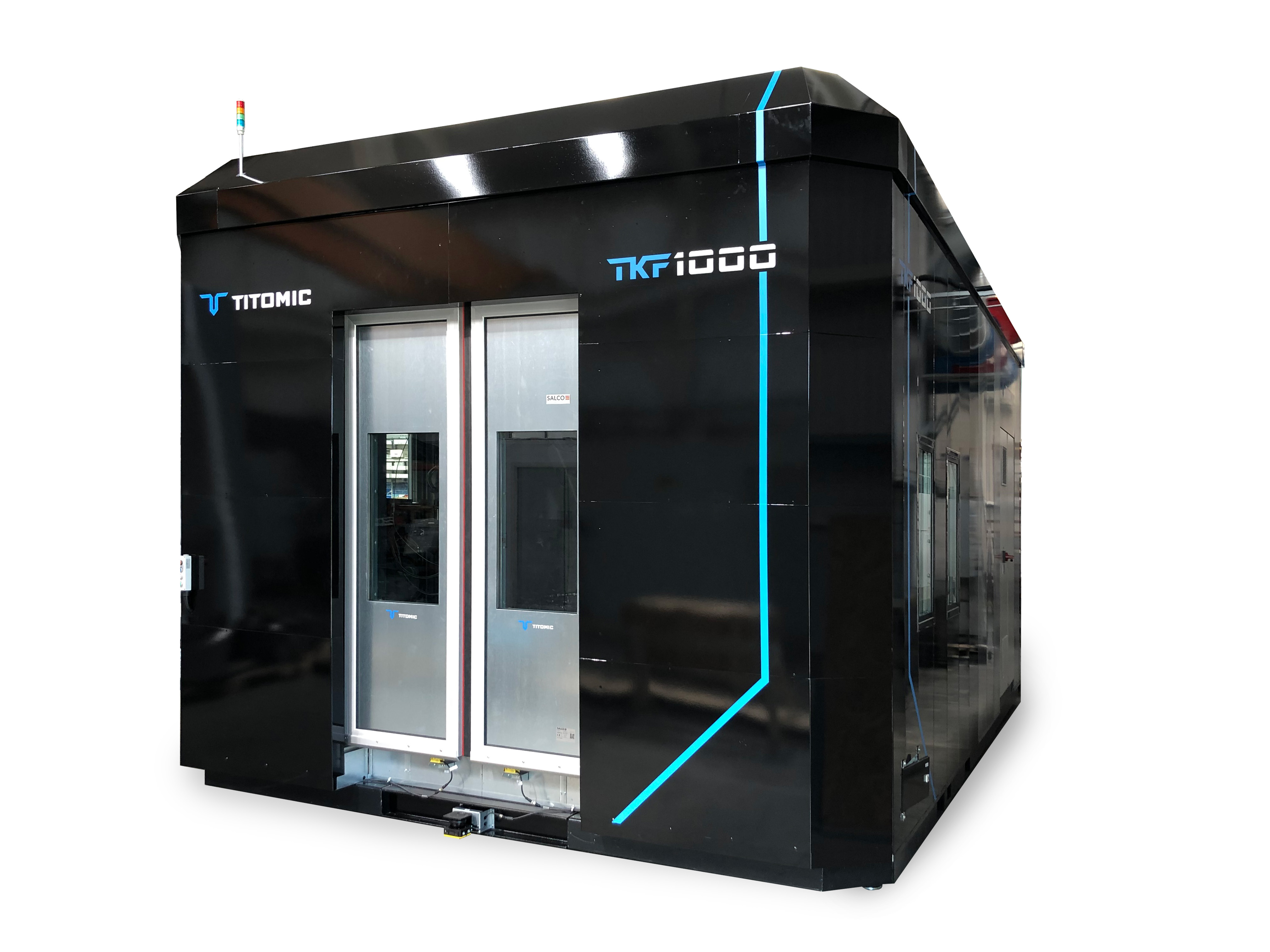

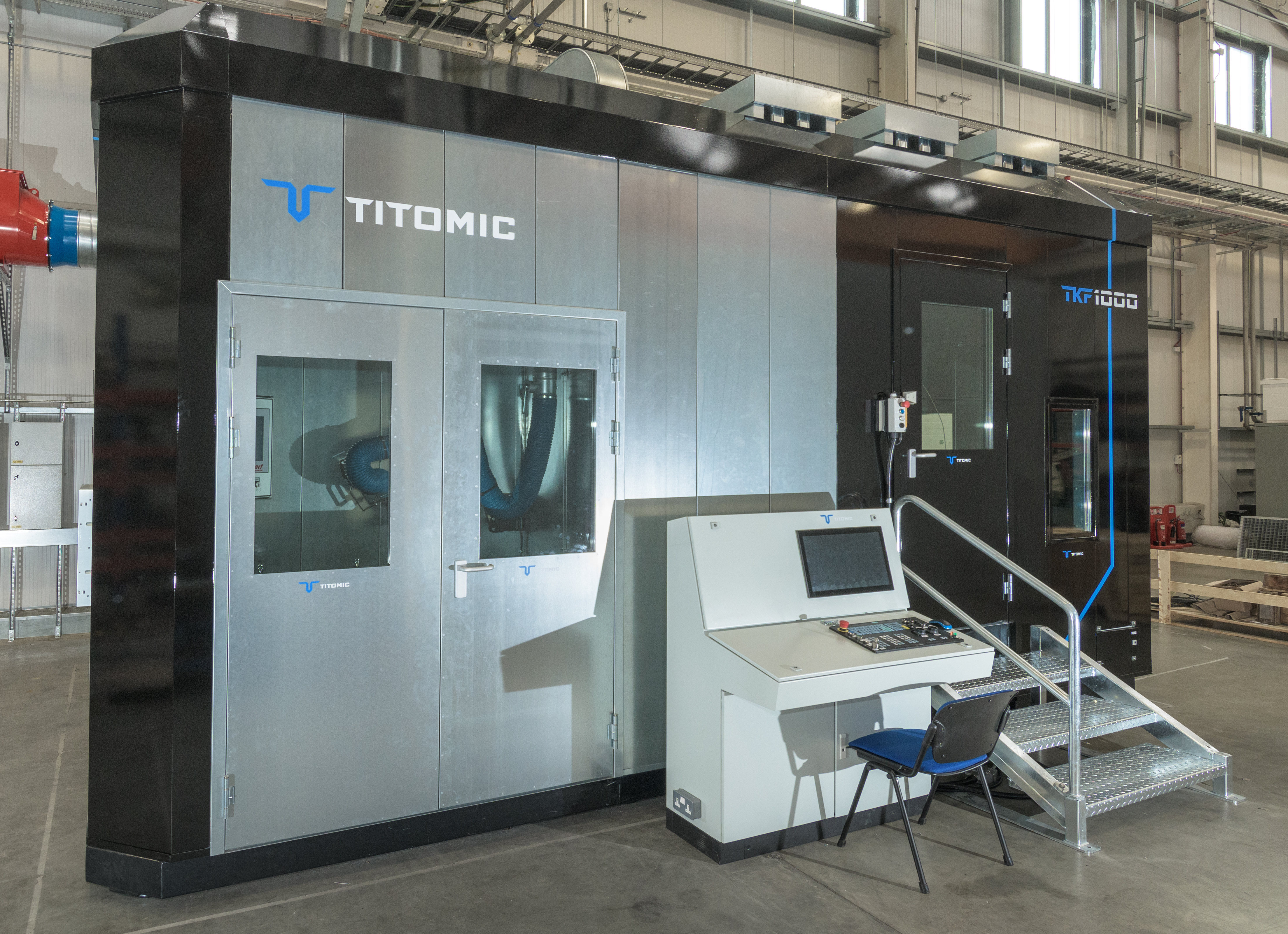

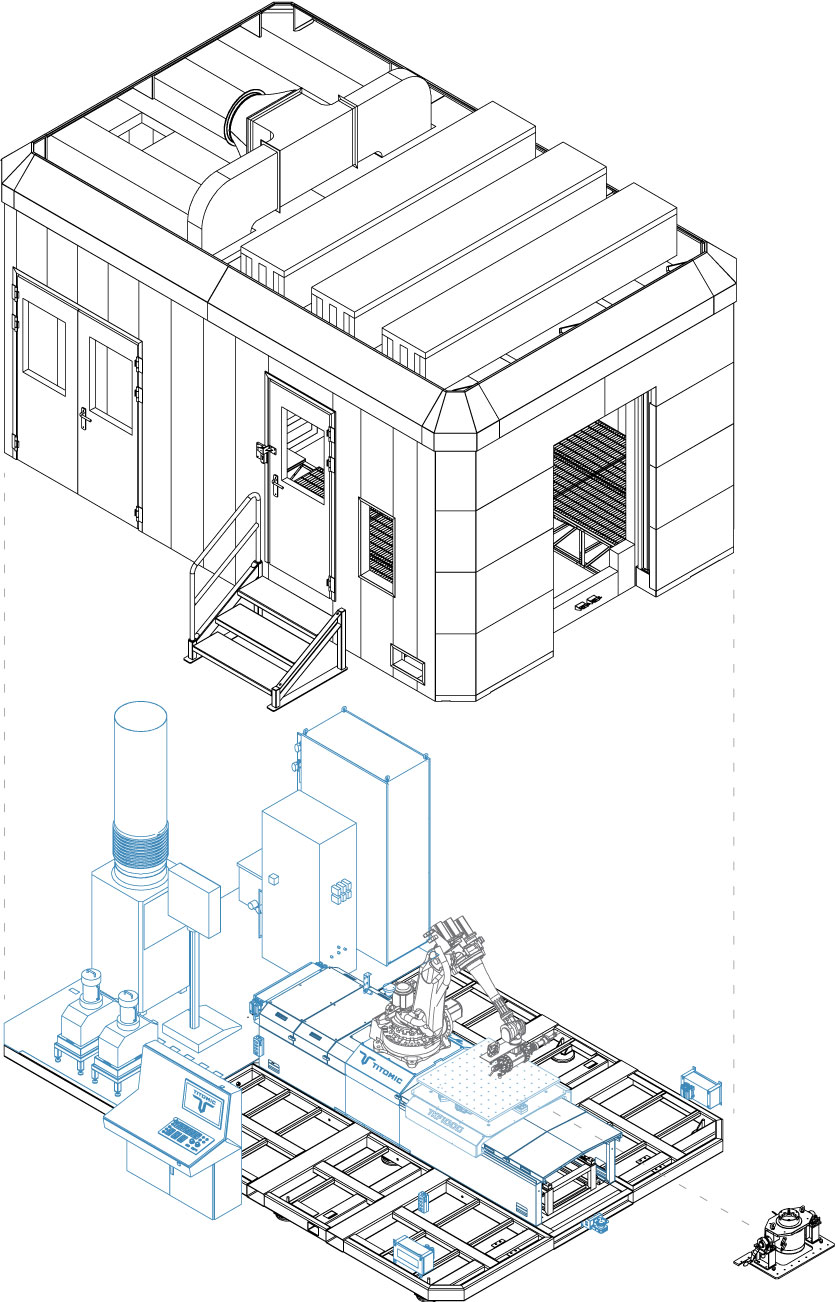

TITOMIC TKF 1000 : Coldspray Technology

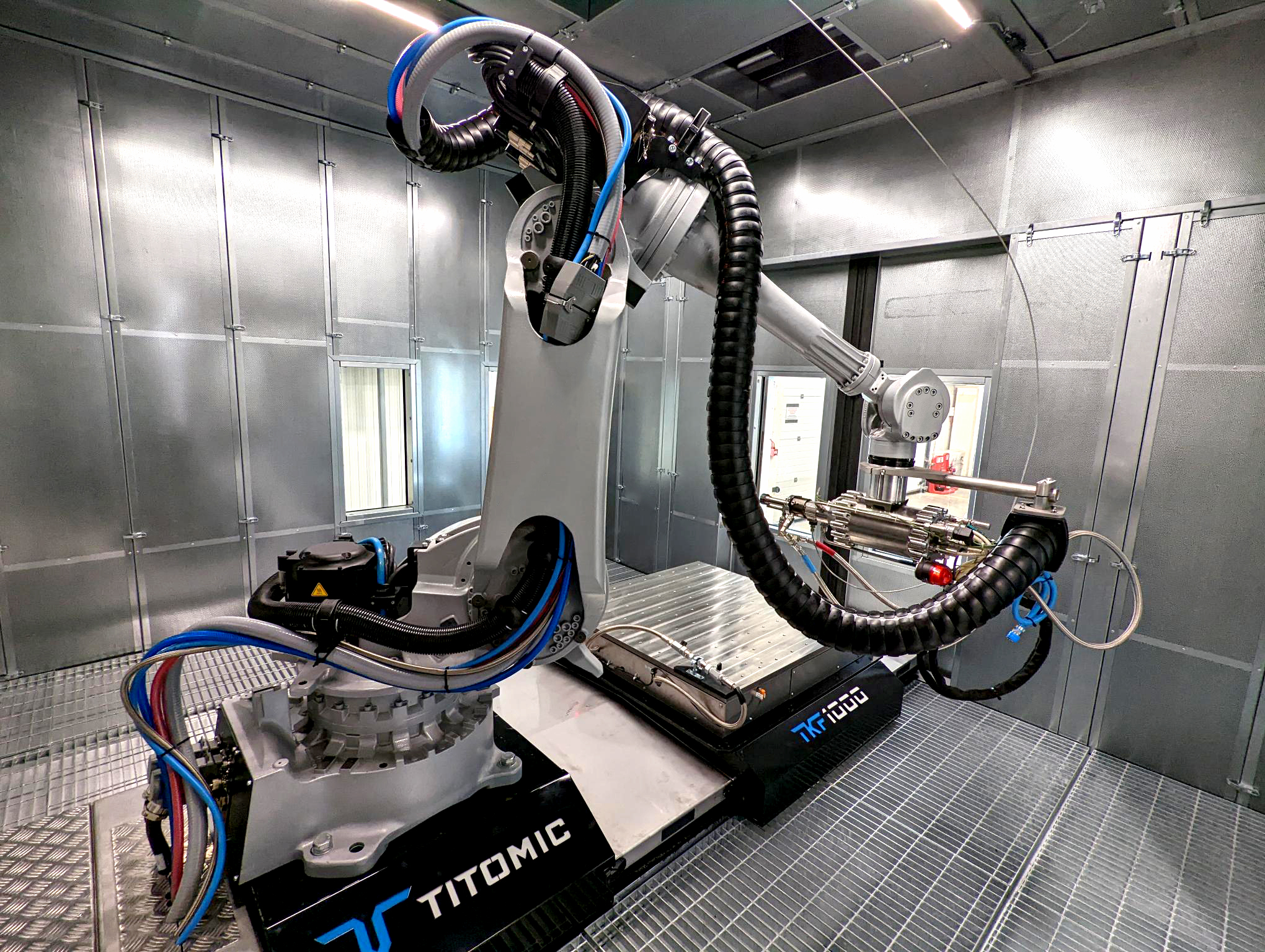

The TKF 1000 system is a turnkey robotic solution. The spraying head is integrated on a robot in a secured robotic cell. It can be used to produce complete parts or reloading and coating operations.

The principle is to accelerate a beam of powder mixed with a gas or compressed air to project it at very high speed onto a substrate. These powders are then fused thanks to their kinetic energy.

TITOMIC robotic systems can produce complete large parts in additive manufacturing, without distortion or oxidation and can combine dissimilar alloys.

FR

FR