29/07/25

Titomic, an Australian pioneer in cold spray additive manufacturing, designs innovative equipment for low-temperature metal deposition. This fusion-free technology makes it possible to restore or reinforce critical components while preserving their structural integrity.

In this case study, Titomic demonstrates the effectiveness of its D523 system for the fast and cost-efficient repair of a mining truck fuel tank—without disassembly or prolonged downtime. By manually spraying nickel onto the identified crack, the part was repaired in under 30 minutes, at a material cost of less than $100.

A concrete illustration of the power of cold spray to extend the life of industrial assets, reduce downtime, and cut intervention costs.

Restoring or repairing large fuel tanks often requires removing them from the vehicle, draining them, rendering them explosion-proof, and then welding. Thanks to cold spray, fuel tanks and other components can be repaired directly on-site, without disassembly.

The fuel tanks of large mining trucks frequently require maintenance to fix cracks and are subject to strict servicing schedules. Typically, repairs involve removing the tank, draining it, and ensuring it’s explosion-proof before any welding can begin.

This multistep process is time- and resource-intensive. When outsourced, it can take weeks—or even months—and generate significant logistical costs. The downtime also translates into lost revenue, as high-value equipment remains idle.

In contrast, cold spray—a low-temperature, solid-state metal deposition process—allows operators to repair fuel tanks on-site, and without removal.

Because cold spray does not introduce heat into the part, it can also be used to quickly repair transmission housings, cylinder heads, shafts, and many other components—without warping or altering the metal grain structure.

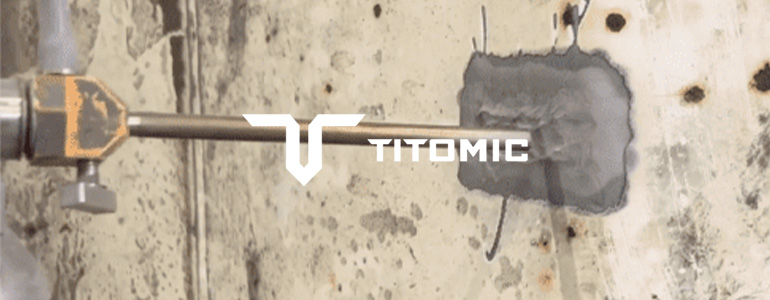

Instead of removing and draining the 5,000-litre tank, Brauntell located the crack and used the portable D523 unit to fill the cavity with nickel. It took only ten minutes to fill the crack, which was then ground smooth—fully restoring the damaged area and returning the tank to service.

From start to finish, the entire repair took just 30 minutes and cost less than $100 in materials. The manufacturer avoided not only a significant repair bill, but also the risk of several weeks—or even months—of downtime and the resulting loss in revenue.

Objective: Repair of a mining truck fuel tank

Location: Brauntell, NSW

How: Low-pressure cold spray system D523 with nickel

Result: Tank repaired in 30 minutes for under $100 in material cost

Damaged fuel tank

Repaired fuel tank.

Source: D523: Fuel tank repair keeps mining trucks moving, Titomic, 03/06/2025.