18/04/23

From personal restoration projects to high-performance upgrades, vehicle customization is a complex process to produce unique components painstakingly handmade by skilled experts. Digitizing this process drastically reduces production time and number of stages while saving money and material costs, however not all 3D printing solutions are able to meet the demands of this application. BigRep 3D printers are indispensable and versatile tools to produce large-scale, quality end use parts and prototypes to redefine the custom automotive industry.

JK Automotive Designs uses BigRep to create custom 3D printed dashboards and panels.

Refurbishing vintage cars with modern interior components is faster and cheaper with 3D printed end-use parts. Printed components and adapters allow new parts to be implemented into a visually undisturbed vintage look.

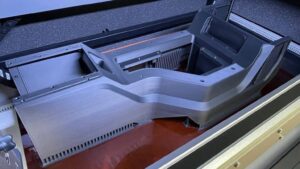

JK Automotive 3D Prints a ‘73 Bronco console.

A fit check is necessary before proceeding with the post process.

The finished console is installed in the car.

Fat Fender Garage 3D prints a 1965 Chevrolet C10 truck dashboard.

The dashboard is post processed.

The finished dashboard is installed in the car.

XENONZ UK uses 3D printed prototypes and patterns to create mold for custom carbon fiber parts.

For carbon fiber exterior components, 3D printed prototypes and patterns streamline the process of creating custom parts that require a perfect fit.

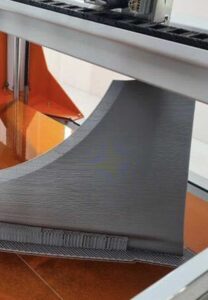

XENONX UK 3D prints the prototype.

The part is post processed and checked for fitting.

A mold is made from the 3D printed positive.

The final carbon fiber part is created with the mold.

Article from our partner BigRep