20/09/22

Millimeter-wave devices (defined loosely as those in the 20-300 GHz range) offer some big advantages. As a result, industry analysts expect the mm-wave market to balloon at over 30% per year for the next decade. Of course, the biggest reason for this is wider bandwidth. Until now, it’s like the world’s telecom authorities divided up a five-GHz pie for hundreds of hungry kids, “Here’s a few megahertz for you. Enjoy! Would you like extra restrictions on top?” But now the telecom authorities are enticing us, “Look, if you can simply get your gizmo to run at 66 GHz, I’ll give you a five GHz slice.” Naturally, these new, quiet, wide bands will provide giant gains in data transmission rates and enable the promise of 5G. But there are other benefits besides higher data rates. Shorter wavelengths mean tiny antennas, thus miniature devices for IoT and medical applications. Short wavelengths also enable steerable and highly collimated beam patterns. Short wavelengths act more like visible light, enabling imaging devices for medical and security applications. The wider bands allow for wider frequency sweeping which translates to much more accurate radar devices with longer range for industrial and automotive applications. Now that these radar devices are technically and economically feasible, governments have begun requiring their adoption in several automotive applications to improve safety.

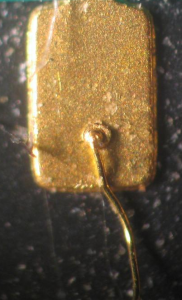

From an RF standpoint, wire bonds mostly work OK for frequencies below 20 GHz, but as the frequency climbs higher into the mm-wave region, these pesky little wires act like freeway lane closures, with more and more cars simply pulling U-turns. The reason for this is that the wires are relatively high in inductance; thus their impedance is directly proportional to frequency. For example, at 10 GHz, 1 mm long wire will have an inductive impedance (reactance) of about 50 Ω, but at 77 GHz, this load jumps to around 400 Ω, wreaking havoc on the signal flow and causing much of the signal to reflect away from its intended destination.

A number of research groups have recently published very encouraging results in the quest for a wire bond replacement for mm-wave applications. For example, Franz Röhrl, Johannes Jakob, Werner Bogner, Robert Weigel and Stefan Zorn have recently published in the International Journal of Microwave and Wireless Technologies that Aerosol Jet printed bonds can outperform wire bonds in the range of 0 to 67 GHz. You can access their work here. In their study, Aerosol Jet printed interconnects were produced using a low-cost PCB substrate, an epoxy gap fill and Aerosol Jet printed silver ink. Insertion losses were measured and compared to those of traditional wire bond packaging.

The authors report that a 6% lower insertion losses at 40 GHz as compared to wire bonds. In addition, there are other advantages to their printed process, including the fact that expensive ENEPIG plating is not required in the Aerosol Jet process, and that substrate surface finish requirements are relaxed as compared to traditional wire bonding methods.

There are other groups using in using Aerosol Jet interconnects for mm-wave applications for both academic and production applications that we’ll highlight in future blogs. A quick scan of the literature will show that Aerosol Jet is now being applied in mm-wave applications from 20 up to as high as 500 GHz. Many are reporting insertion losses of the Aerosol Jet interconnects that are on par with etched copper traces.

Maybe we can finally get rid of the bell-bottoms.