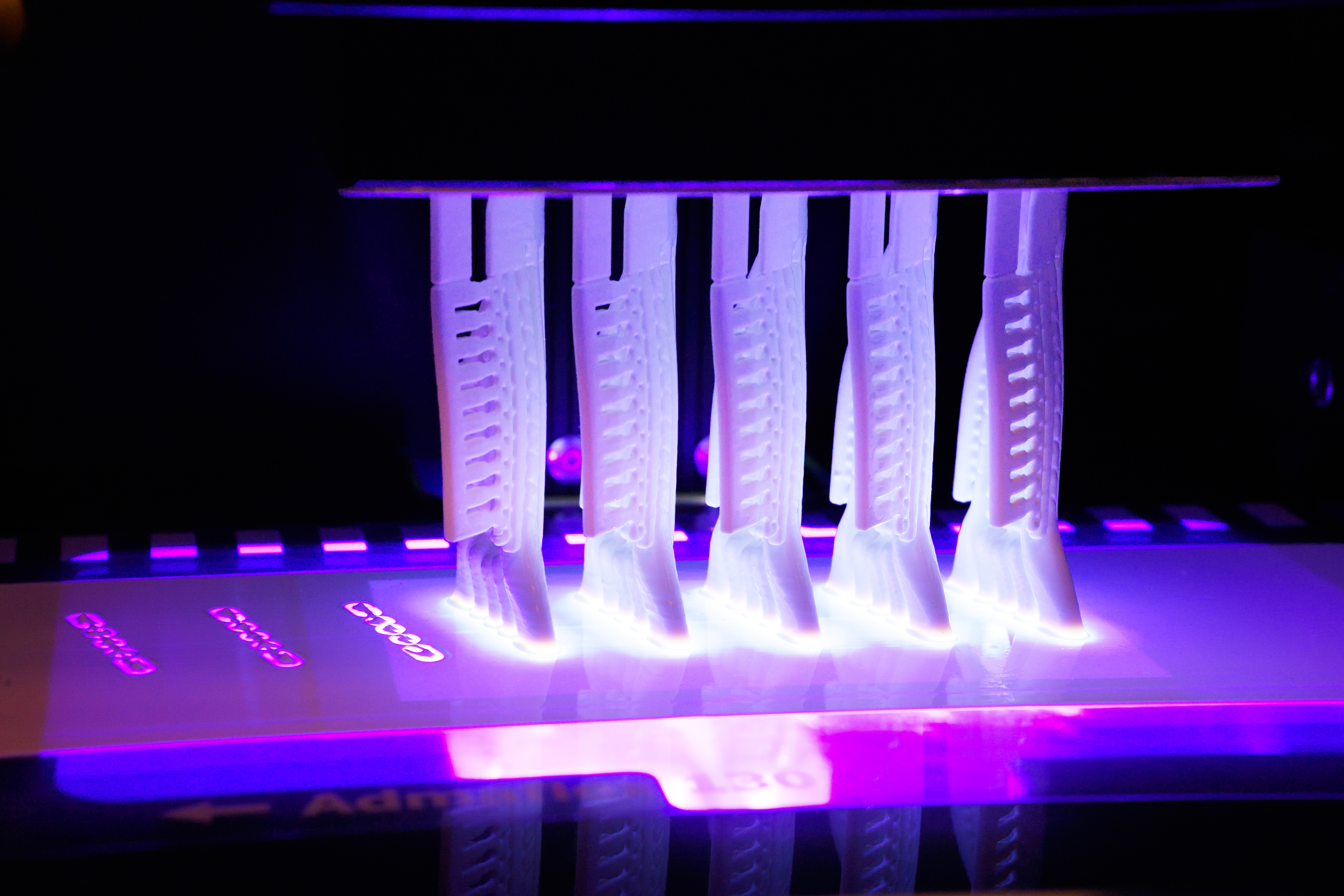

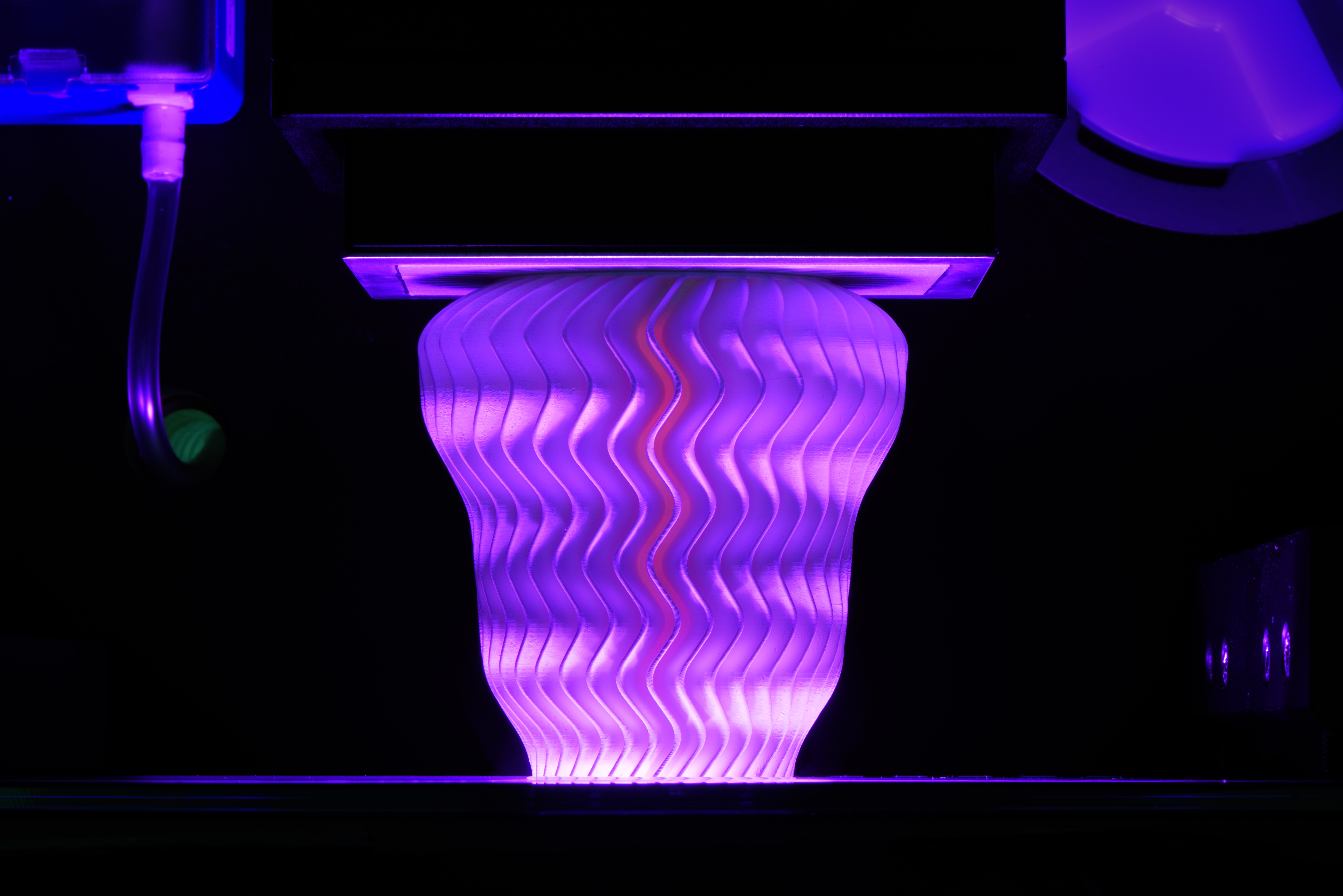

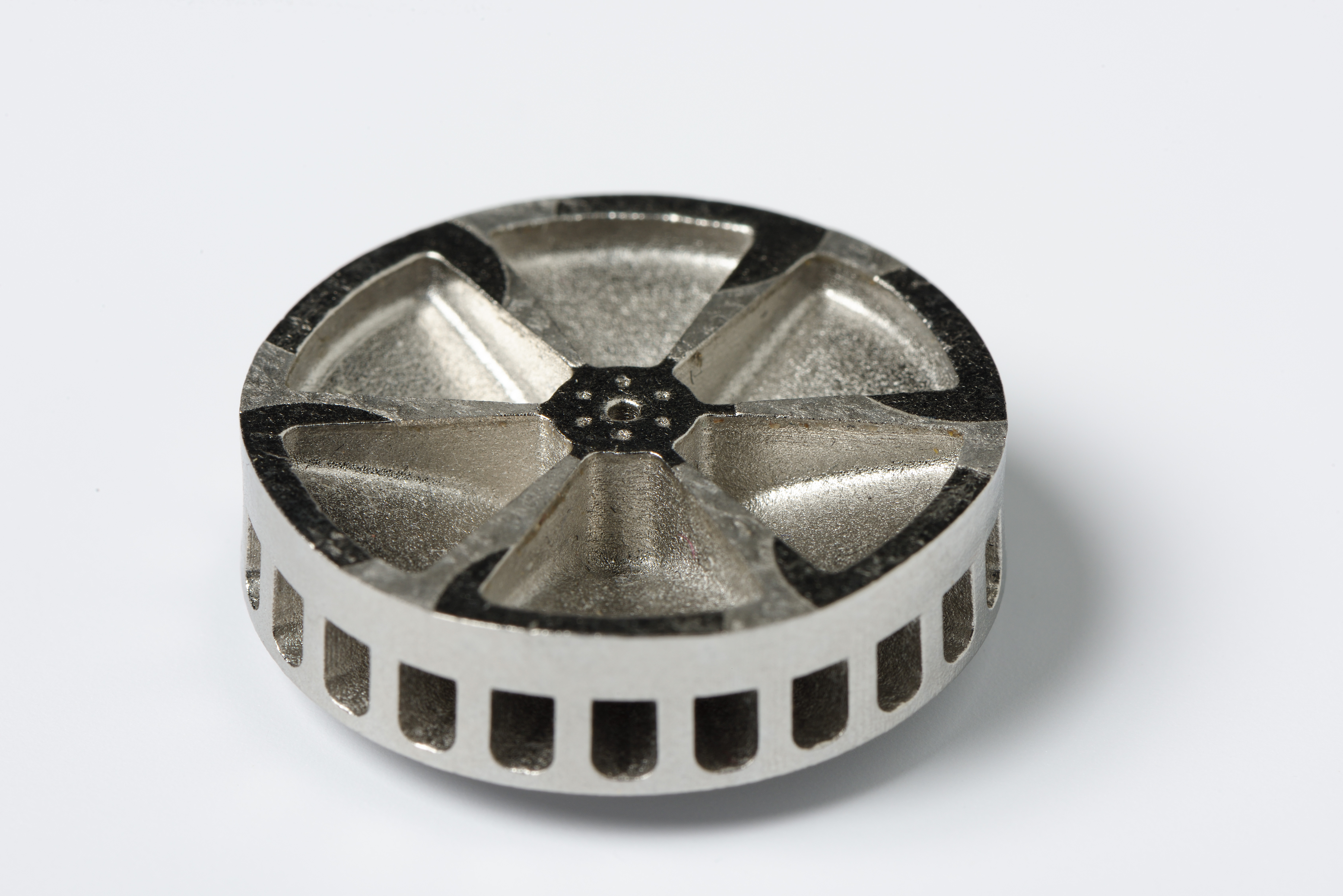

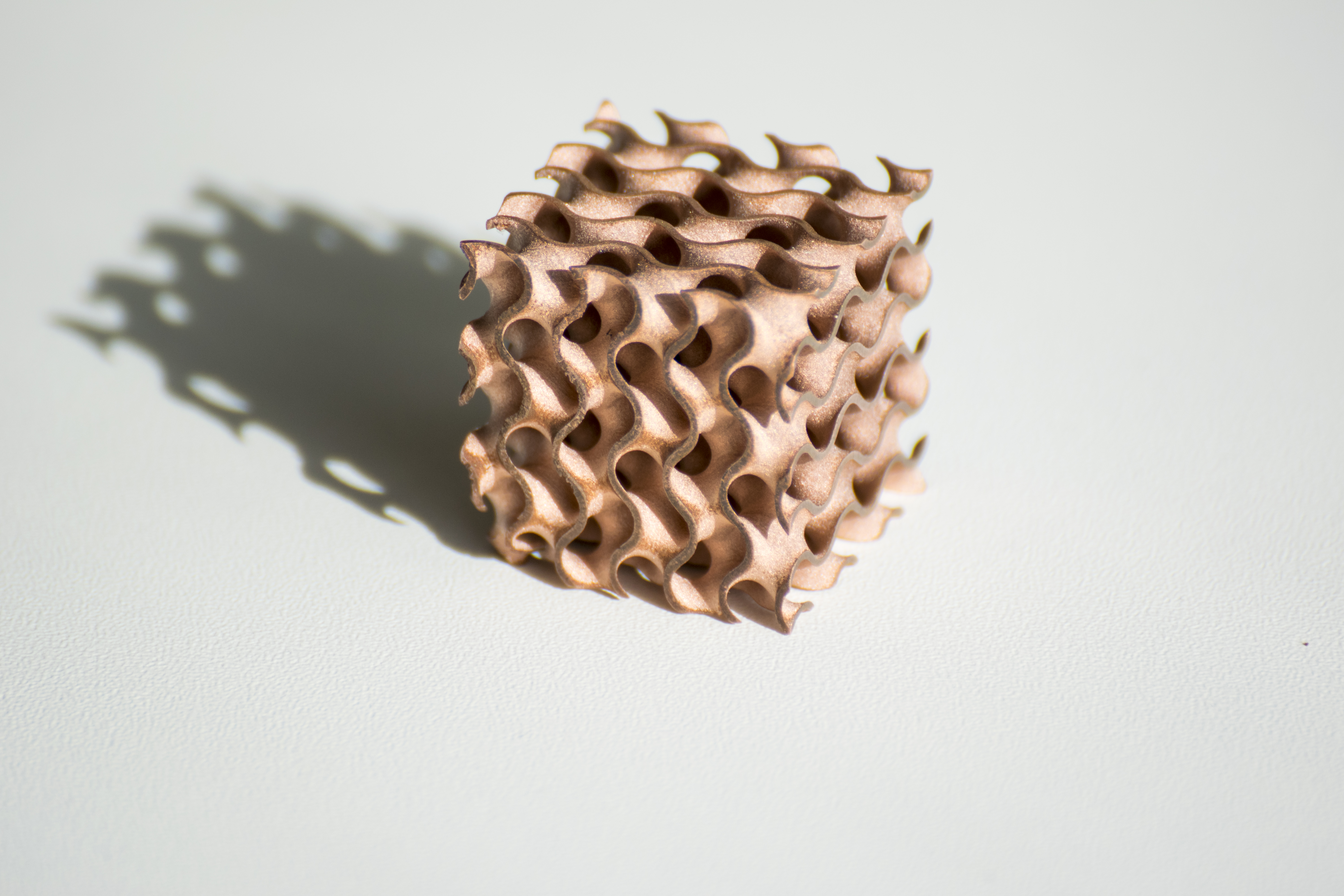

Admaflex 130 Evolution : A multi-material 3D printer

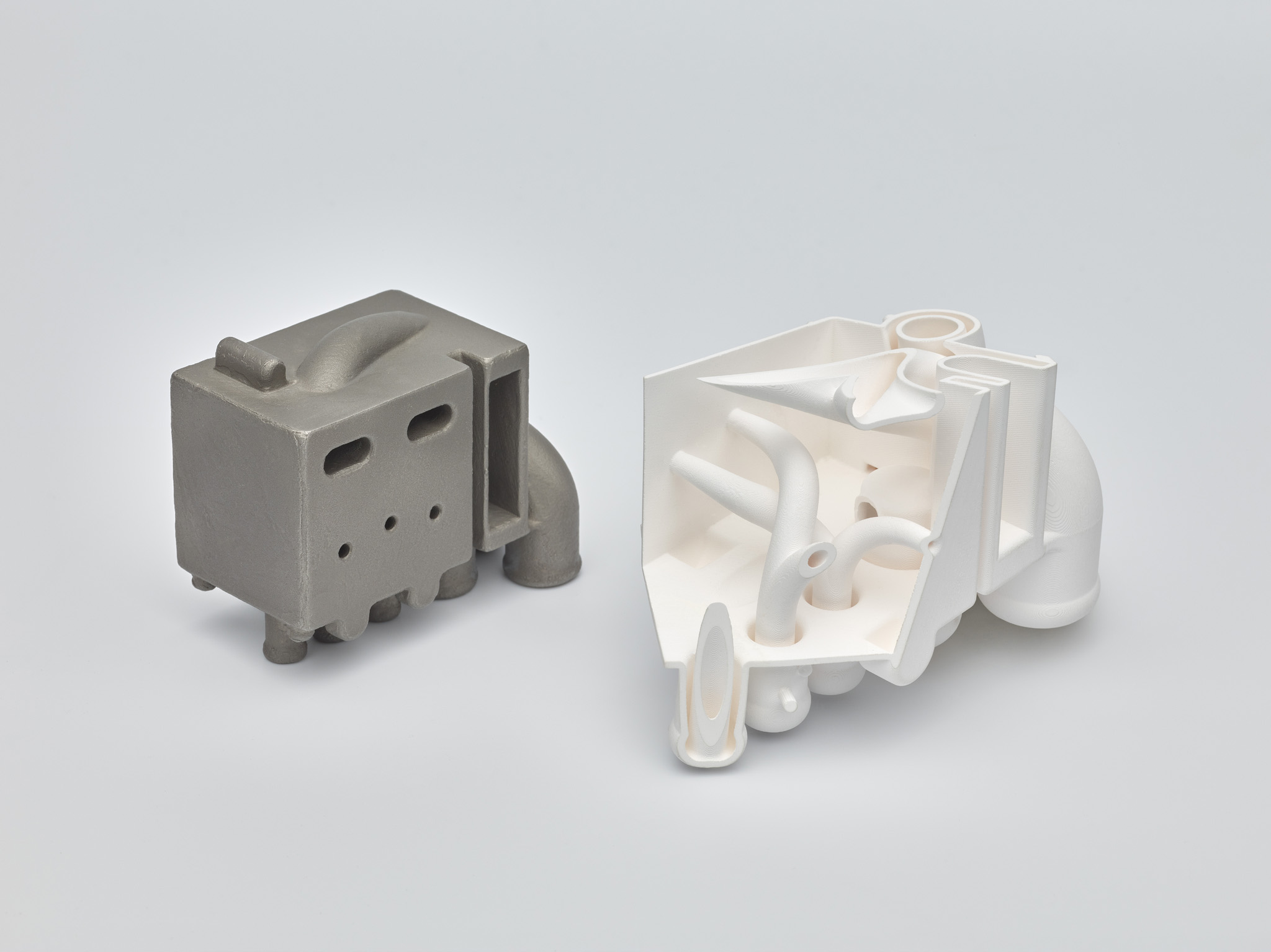

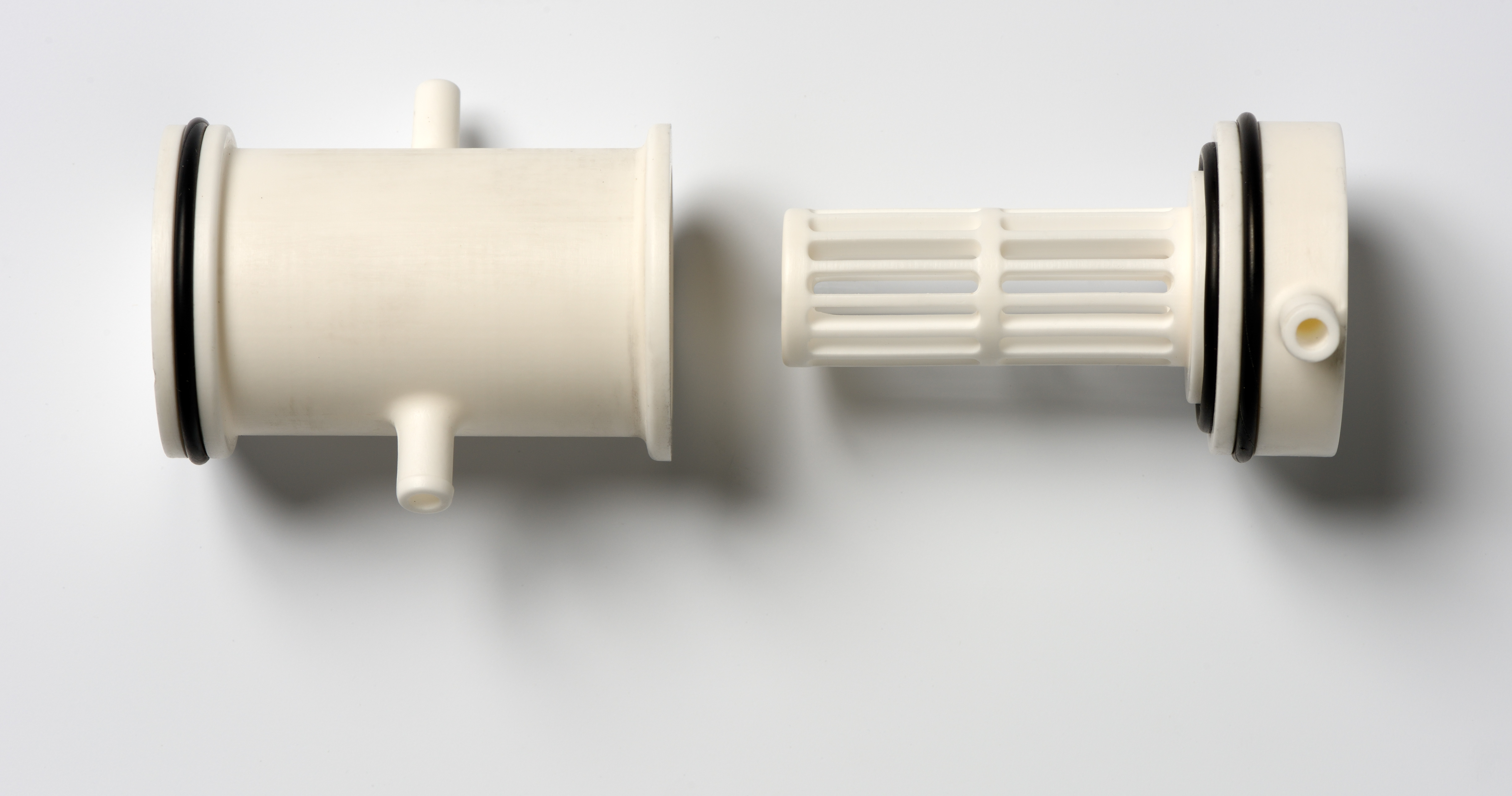

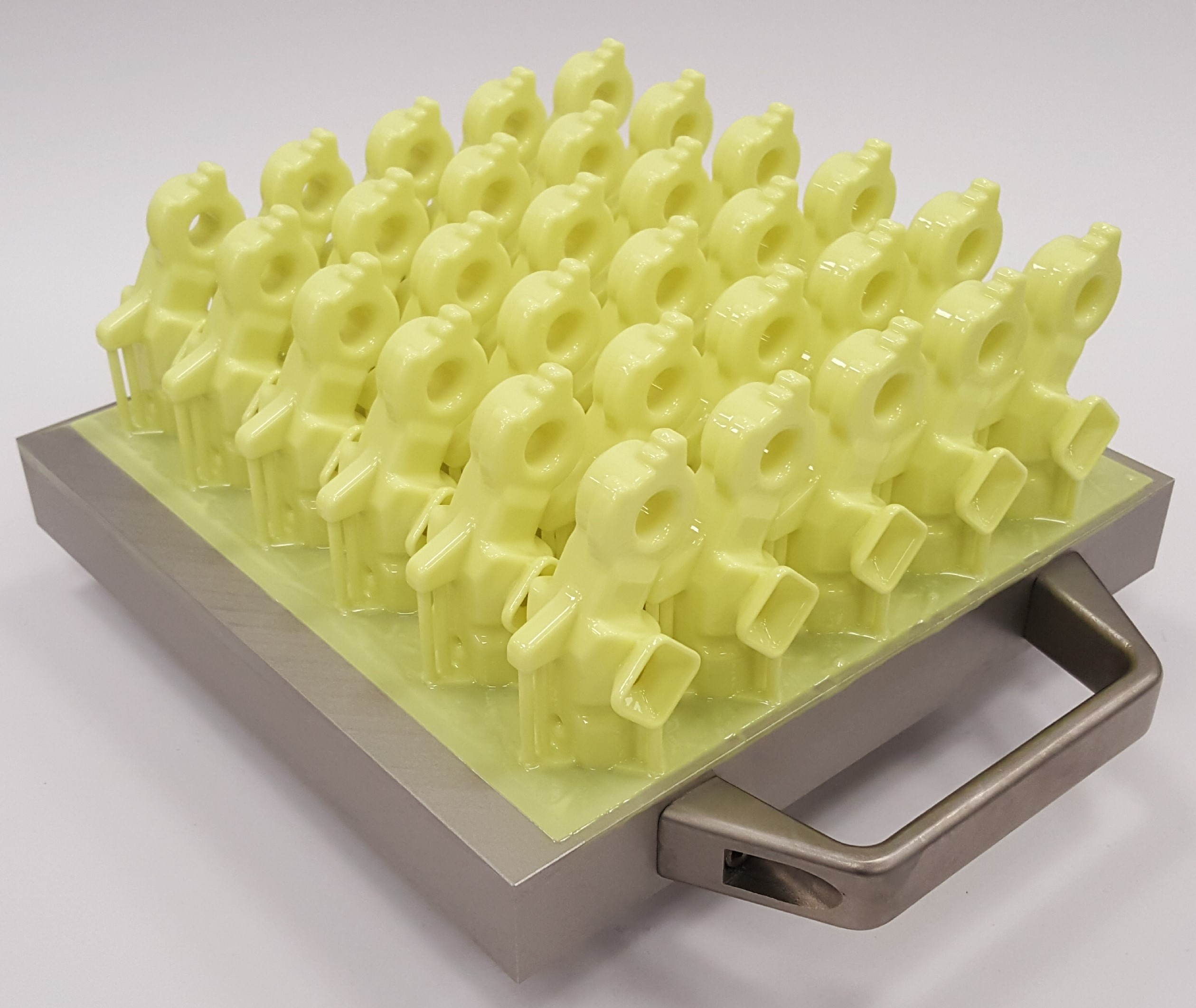

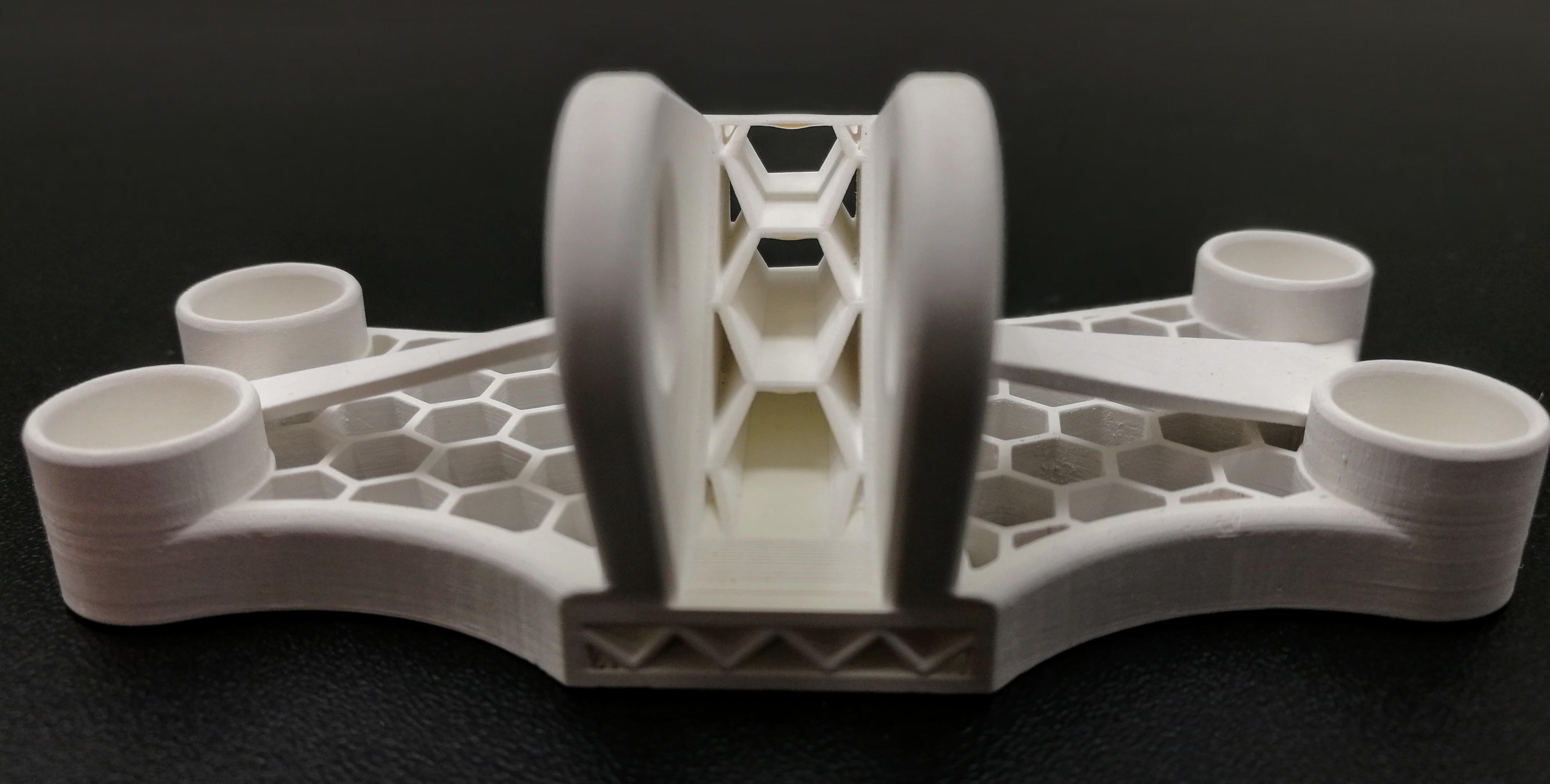

Two materials, one machine, the Admaflex 130 Evolution is suited for 3D printing both ceramic as metal precision parts. Through an optional add-on, the ceramic 3D printer is suited to print metals too. This unique add-on supports high dense materials in staying homogeneous throughout the printing process, to optimize each layer. The advanced patented Admaflex Technology has an innovative material reconditioning system to minimize waste to none.

High resolution

The integrated DLP light engine allows for large surface printing, while maintaining precision and resolution, to produce even the smallest sized features in full detail.

Open architecture

The Admaflex 130 is set up with an open architecture, providing layer-to-layer control to define printer settings, easily accessible through an adaptive touch screen.

Customized materials

Though AdmaPrint products achieve the best printing results, the open architecture also enables using in-house developed materials.

FR

FR