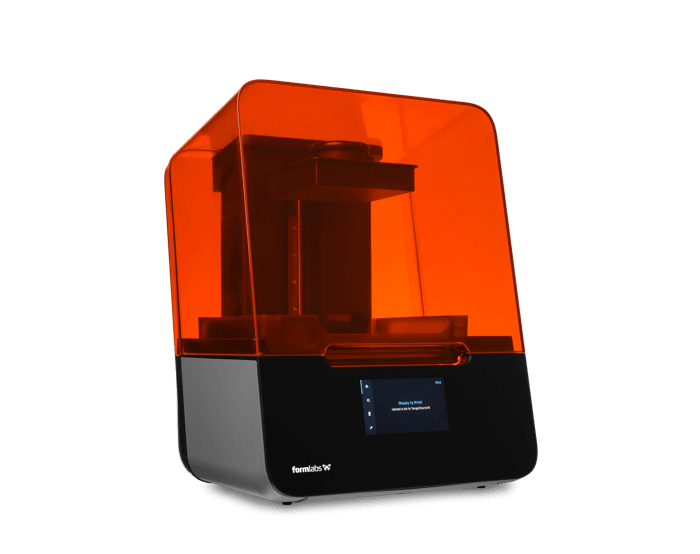

FORM 3+

SPEED AND PERFECTION IN EVERY PRINT

The Formlabs Form 3+ printer is an upgraded version of the Form 3. It uses Low Force Stereolithography printing technology to print quality parts with excellent surface finish. This SLA 3D printer is simple to install and maintain. It has many improvements that make the Form 3+ an ideal SLA printer for professionals who want to combine precision and quality.

LFS TECHNOLOGY

LFS technology brings more precision to printed parts. Indeed, this technology is an improved version of SLA 3D printing.

POST TREATMENT

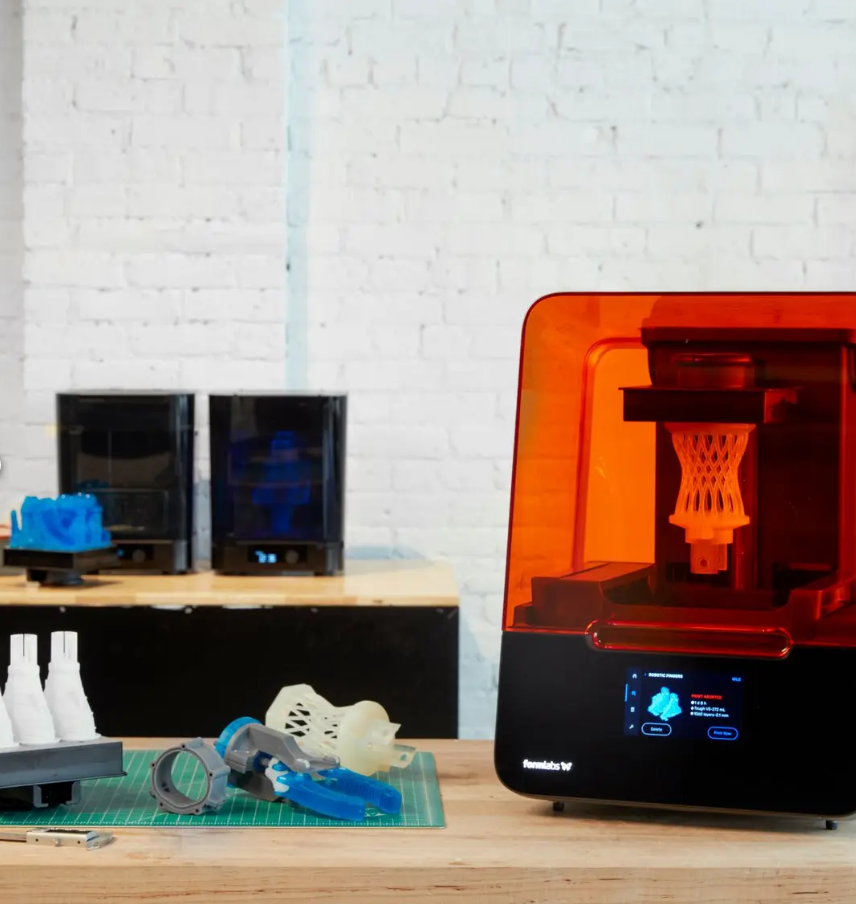

The Form 3+ makes it possible to print easily processable supports. The post-processing of the parts can then be done easily thanks to the Form Wash and the Form Cure.

PRINT SPEED

The Form 3+ offers its users increased printing speed. It saves printing time and prints parts in record time.

USE AND CARE

Formlabs offers an easy to use and maintain LFS printer. The Form 3+ has been designed to provide a truly simple and intuitive user experience.

COMPATIBLE RESINS

Formlabs offers many resins compatible with the Form 3+ printer. This wide choice offers the possibility of carrying out many professional applications.

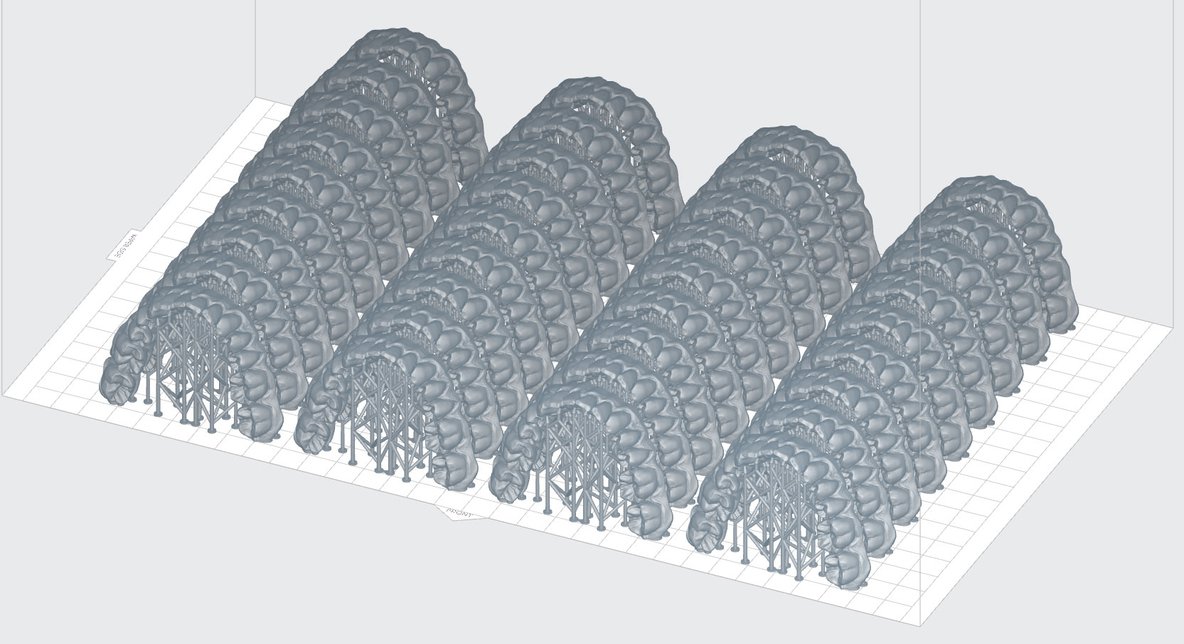

SOFTWARE PREFORM

The PreForm software allows you to configure your model in a few clicks, to launch a print remotely and to monitor its evolution thanks to the Dashboard.

FR

FR