Applications

The range of Heat and Vacuum Applicator (HVA) machines are designed to apply decorative engineered laminates to aircraft interior panels:

- Sidewalls

- Dado panels and Trim

- Ceilings

- Bulkheads

- Seating shells

- Emergency exit doors

AIRCRAFT LAMINATES AND MORE

The HVA machines are a type of vacuum press mainly used by aircraft manufacturers, airlines, third-party maintenance shops and subcontractors. They can also be used to apply leather to car interiors, or to laminate furnishings such as car roofs and dashboards. That means they can be used to produce interior elements for a wide range of vehicles – not just aircraft, but cars, trucks, trains, boats and buses.

We often sell heat and vacuum applicators to the automotive industry, and one interesting use is for applying graffiti resistant films to train interiors.

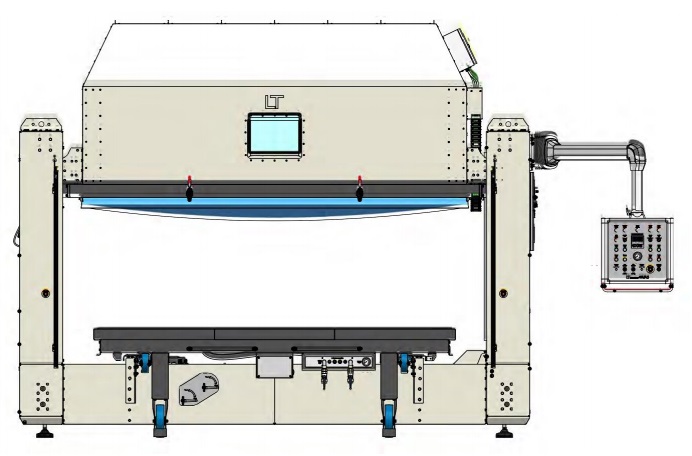

HOW DOES IT WORK ?

A shortwave infrared radiation heating system is used to soften the laminate prior to forming. Then a vacuum membrane system forms the laminate to the surface of the panel.

Our HVA machines provide accurate control and avoid glossing or texture washout of the engineered laminate being applied. The machine will form and bond the laminate into deep recesses without popping or bubbling.

Our HVA vacuum presses are supplied with a Universal Tool that puts you straight into production without having to purchase lots of heavy rigid tooling.

HEAT VACUUM APPLICATOR MACHINES

These heat vacuum applicator machines are the result of 50 years’ experience in cabin interior work.

- Quick, minimum-fuss installation

- Designed and built for a very long life

- Honed and refined

- High quality, robust and reliable

- Low maintenance

- Supplied worldwide

- Highly responsive infrared heating

- Class-leading temperature control

- Excellent vacuum press power, with an integral vacuum pump

HVA 3

The new HVA-3 machine covers all sidewalls and can be used for seating shells and suites for First Class and Business Class. Panels such as 777-300 ceiling panels and overhead bin doors can also be handled.

HVA 4

The HVA-4 has a larger bed. It can handle all the HVA-3 work, as well as larger panels and multiple loading. The HVA-4 has additional automation of the moving parts.

FR

FR