The result of intelligent evolution !

Every KERN Evo contains many years of consistent development to ensure ultra-high precision in CNC milling at high and medium volumes.

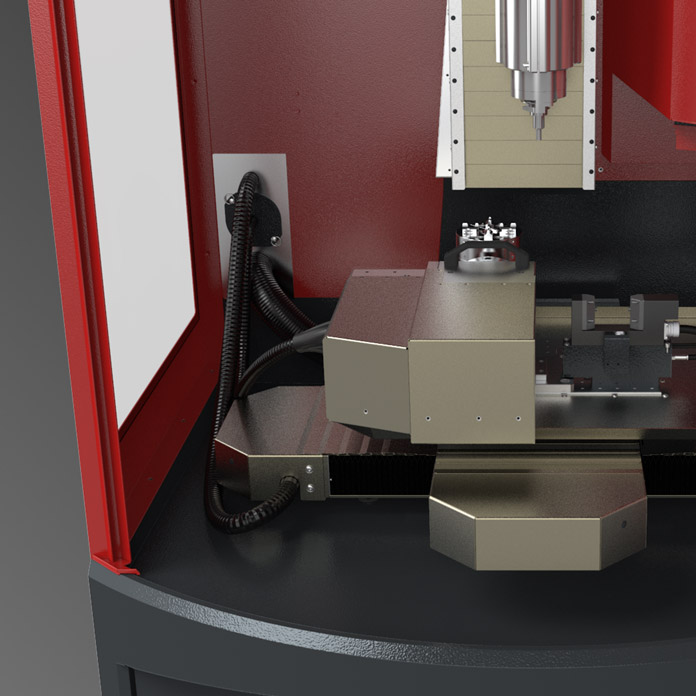

With its proprietary X-Y cross table, KERN Evo delivers maximum precision in a small installation space. The design allows maximum smoothness and excellent surface finish (Ra < 1 μm) even at high speeds and acceleration values.

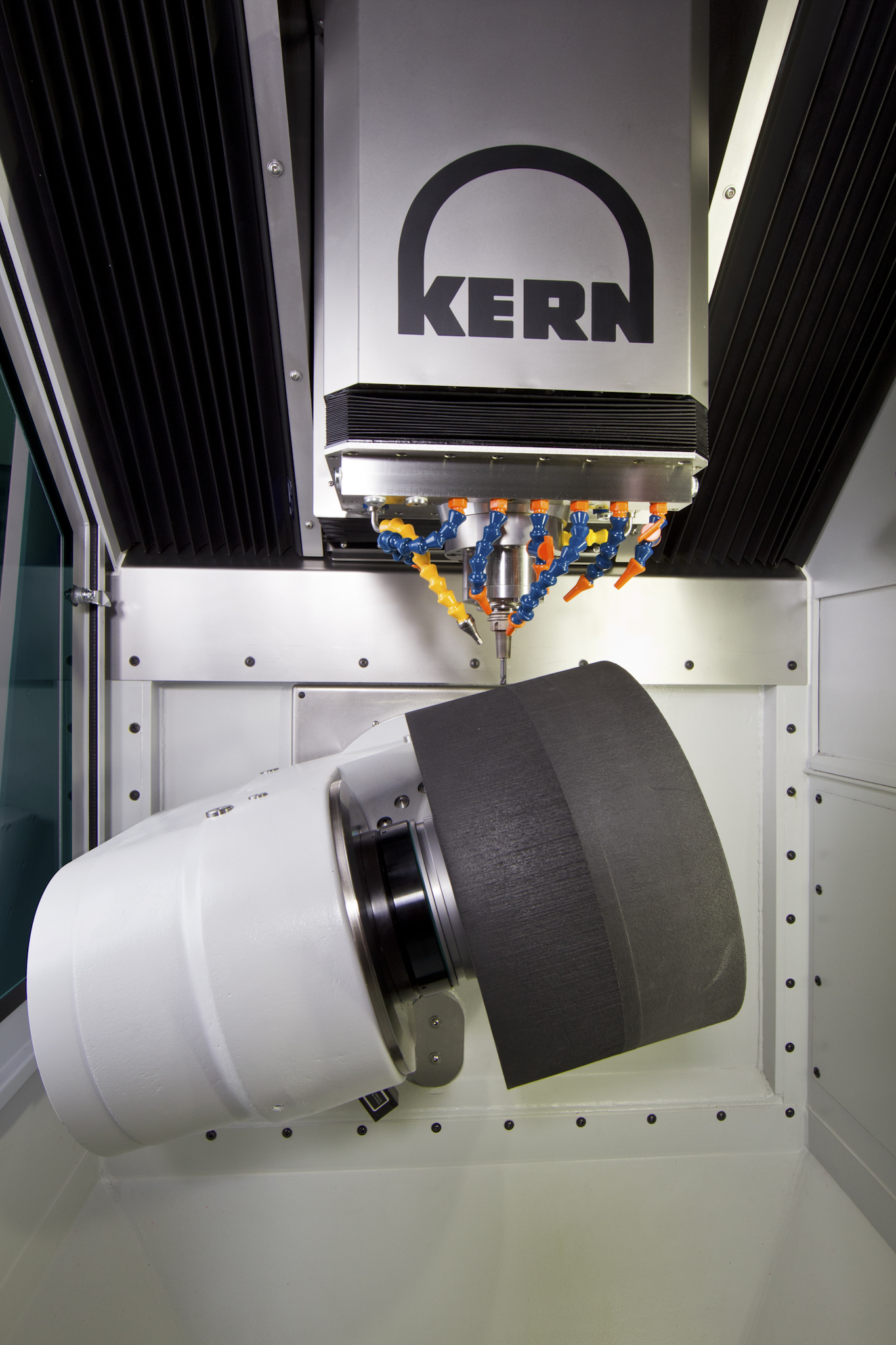

Short distances between components and drives ensure minimal angle errors, while ultra-high resolution direct measuring systems guarantee maximum repeat accuracy in a working space of 300 x 300mm. KERN Evo can be optionally equipped with a 4th and 5th axis without compromising the stability and high precision of the basic machine.

With high quality components in all peripheral modules and easy automation, KERN Evo is widely used for unmanned 3-shift production in all industries that demand maximum precision on the workpiece.

Features and benefits at a glance

High precision on the workpiece

The axes are designed for extreme precision and provide the basis for the machine’s outstanding basic accuracy. Ongoing improvements in the components and control processes help to further increase precision on the workpiece and manufacturing productivity.

Outstanding surface quality

Its unique machine frame made of mineral casting gives the KERN Evo a high degree of stiffness that is essential when machining high-precision surfaces. It is insensitive to thermal influences and up to ten times better at vibration damping than conventional GG20. In addition to the quality of the installed components and the solid installation, these factors provide the basis for exceptional surface quality on the machined parts.

Optimal ergonomics

The clear and balanced machine design allows full access to the working space as well as free access to the clamping surface. Thus, efficient operation is easily ensured – even in non-automated production.

Flexible and fully automatable

A comprehensive range of modules and accessories enables the KERN Evo to be tailored to your requirements and applications. Automatic workpiece loading systems can be integrated seamlessly into the machine and optimized for each application. Even after delivery, we are ready to support you with process creation and production optimization.

FR

FR