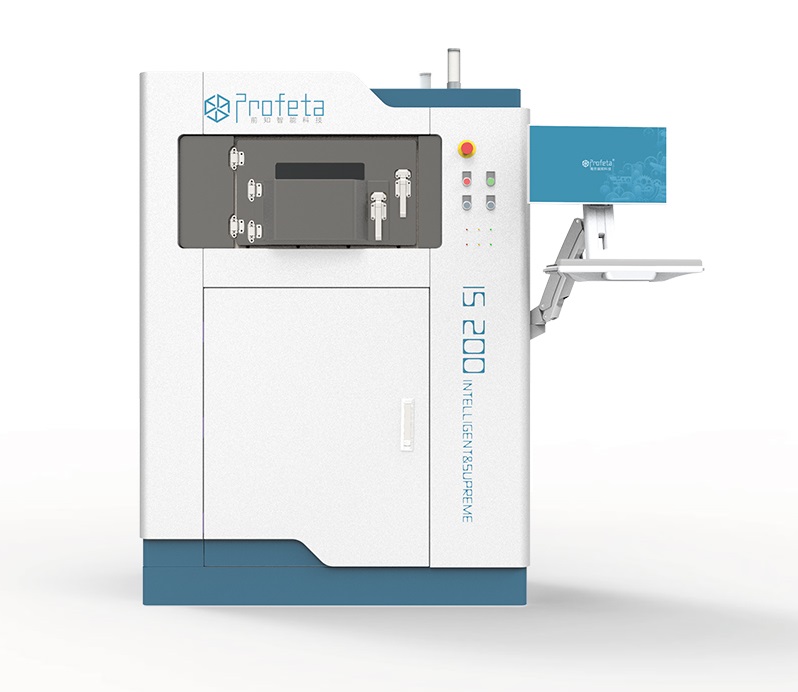

It has a large volume of construction : 250 x 180 x 70 mm (X,Y,Z) and is dedicated to the production of parts for the dental sector, crowns and stellites in cobalt chrome and titanium.

Dedicated Dental Metal 3D Printer

- Main force model for highest volume production;

- High-end machine with advanced algorithm and components brings the fastest printing speed (4.5-5.5hrs for 400 copings/36 RPD frames);

- The building volume (250*180*70mm) brings the highest volume per batch and reduces times of operations by 50%;

- The highest powder utilization (500-600 copings or 50-60 RPD frames/kg of powder);

- Proved stability in domestic and global market.

One-stop Solution Package

- The one-stop solution package includes design software, slicing software, furnace, automatic screening cabinet and nitrogen generator;

- Our solution achieves synergy effects for better quality and efficiency

Customer Value

- Designed for high production labs and printing centers;

- The highest volume production, minimum personnel cost and the highest powder utilization achieve the lowest cost per unit production;

- Proved machine stability.

FR

FR