OPERATION

The scanner is equipped with two cameras, which acquire the laser projection on the object. The laser projection becomes distorted as the scanner moves around the object. The position in space of each point constituting the line projected by the laser is calculated with great precision by triangulation, thanks to the known spacing of the two cameras.

The scanner identifies its spatial position using visual markers on the object’s surface during scanning, which allows the position of points to be recorded in a single landmark.

The position of the points is calculated when the laser passes over them. The scanning of the laser on the part, combined with the calculation of the position of the scanner, thus creates the continuous surfaces.

CHARACTERISTICS

HIGH ACCURACY

- A resolution of up to 0.030mm

AUTOMATIC POSITIONING

- No need for additional positioning device

DYNAMIC MEASUREMENT

- Ensures full freedom between the scanner and the object

REAL-TIME VIEWING

- Point cloud without superposition; automatic generation of 3D solid visualizations (triangular mesh)

ANTI-INTERFERENCE

- The precision is insensitive to the unstable environment; the scanner allows you to work normally in direct sunlight

HIGH ADAPTABILITY

- Effectively processes shiny or black surfaces, most of the time imaging enhancement is not necessary.

WIDE RANGE OF USES

- Easily scan different object shapes from the size of an egg to that of an airplane

SIMPLE OPERATION

- Portable measuring tool, use in tight spaces, easy handling (weight less than 1 kg)

VOICE INDICATIONS

- Voice guidance assists the operator in his work

WORKING OVER LONG DISTANCES

- Gigabit Lan connection allows working over long distances

CONTROL AND POST-PROCESSING SOFTWARE

SCANVIEWER

The ScanViewer software, supplied with the scanner, enables data processing during and after the scan. It allows you to view the scan in real time and to manipulate the acquisitions.

It includes the following features, among others :

- Clipping parts with automatic background detection

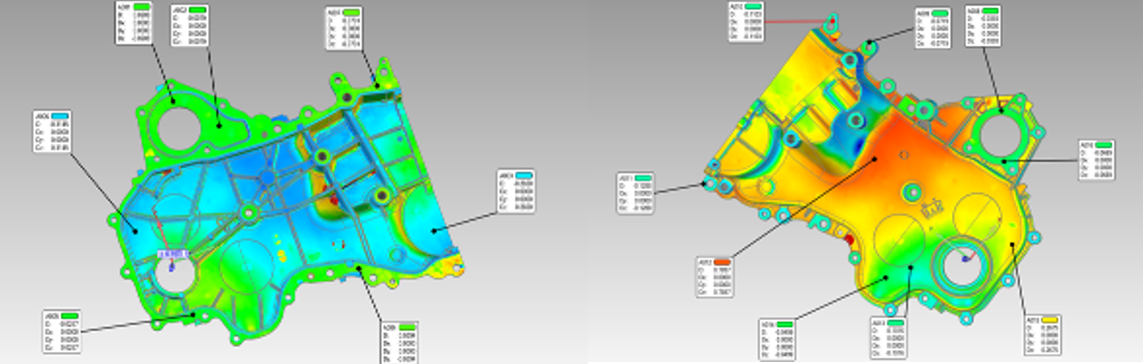

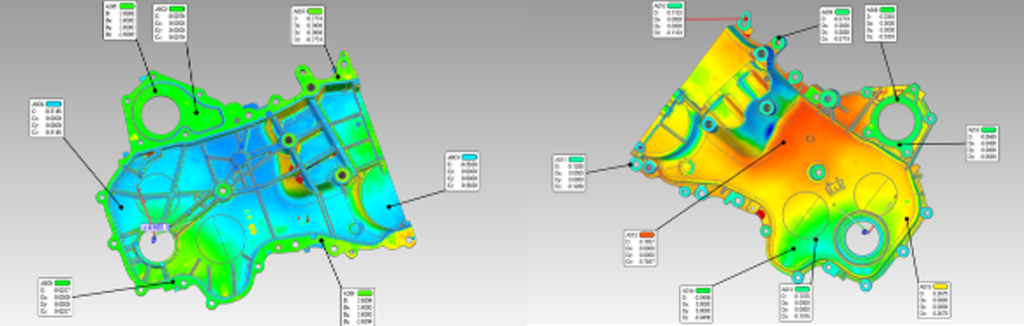

- Analysis of measurement deviations from a reference CAD

- Measurements of: dimensions, sphericity, cylindricity, flatness, parallelism, perpendicularity, concentricity.

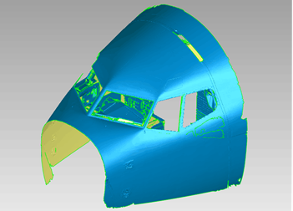

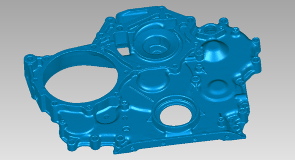

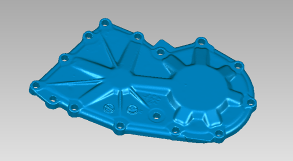

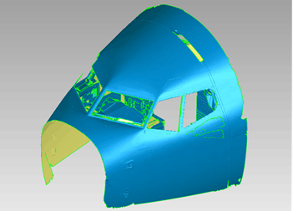

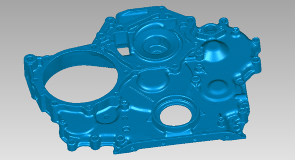

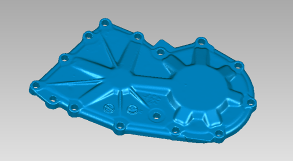

Reverse engineering of a foundry part

Dimensional control

FR

FR