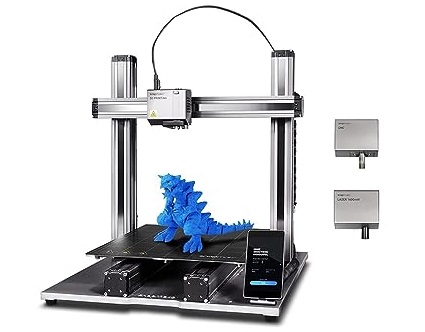

Snapmaker 2.0

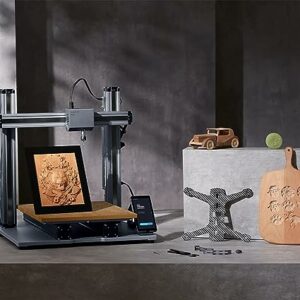

3 manufacturing techniques, 1 single machine

In addition to its versatility thanks to its 3 manufacturing techniques, a 3-in-1 machine also saves space and saves considerable money. This is why the Snapmaker 2.0 is a printer of choice for fablabs, the education sector, non-professional users, makers and craftsmen.

Changing from one function to another is done in just a few seconds.

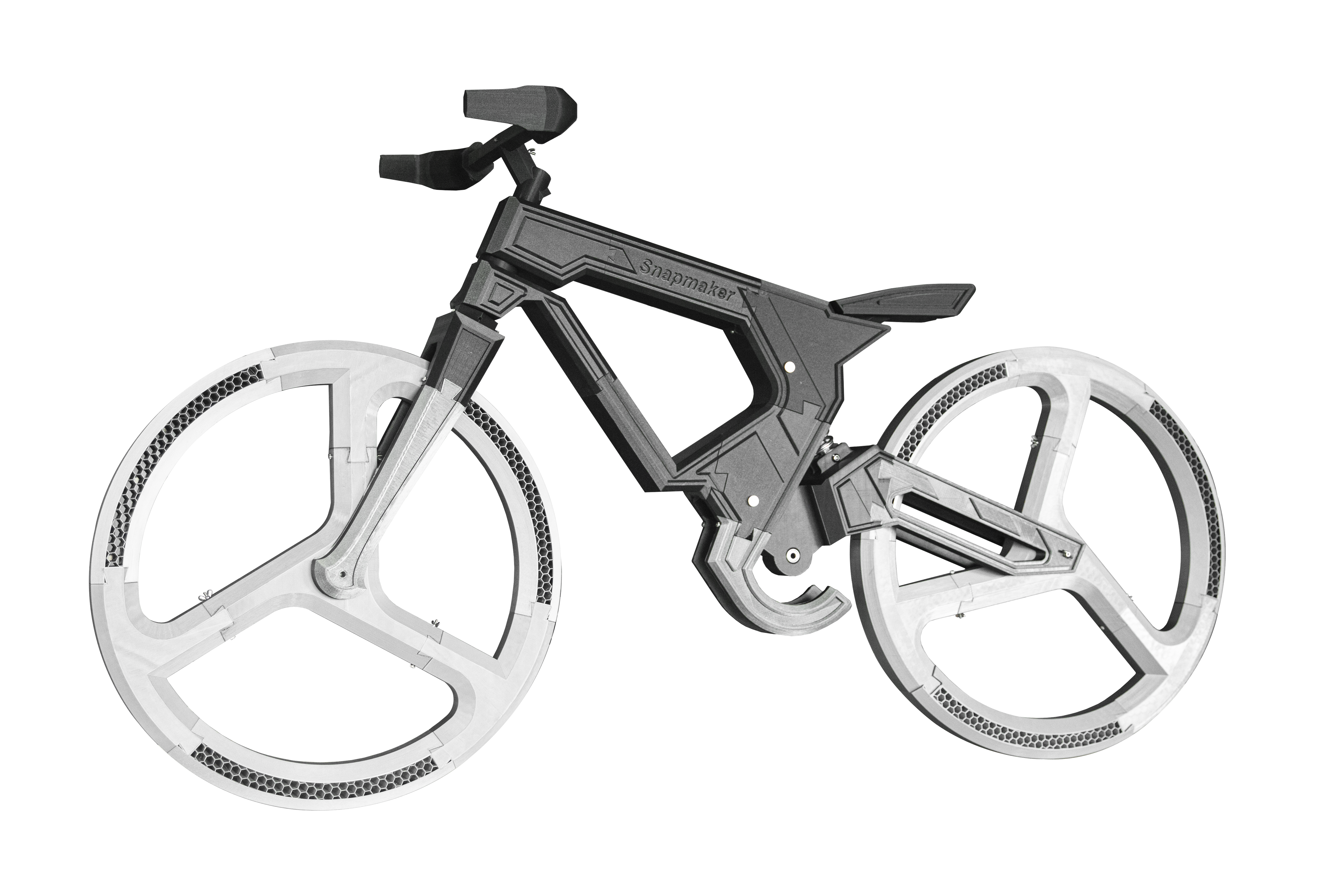

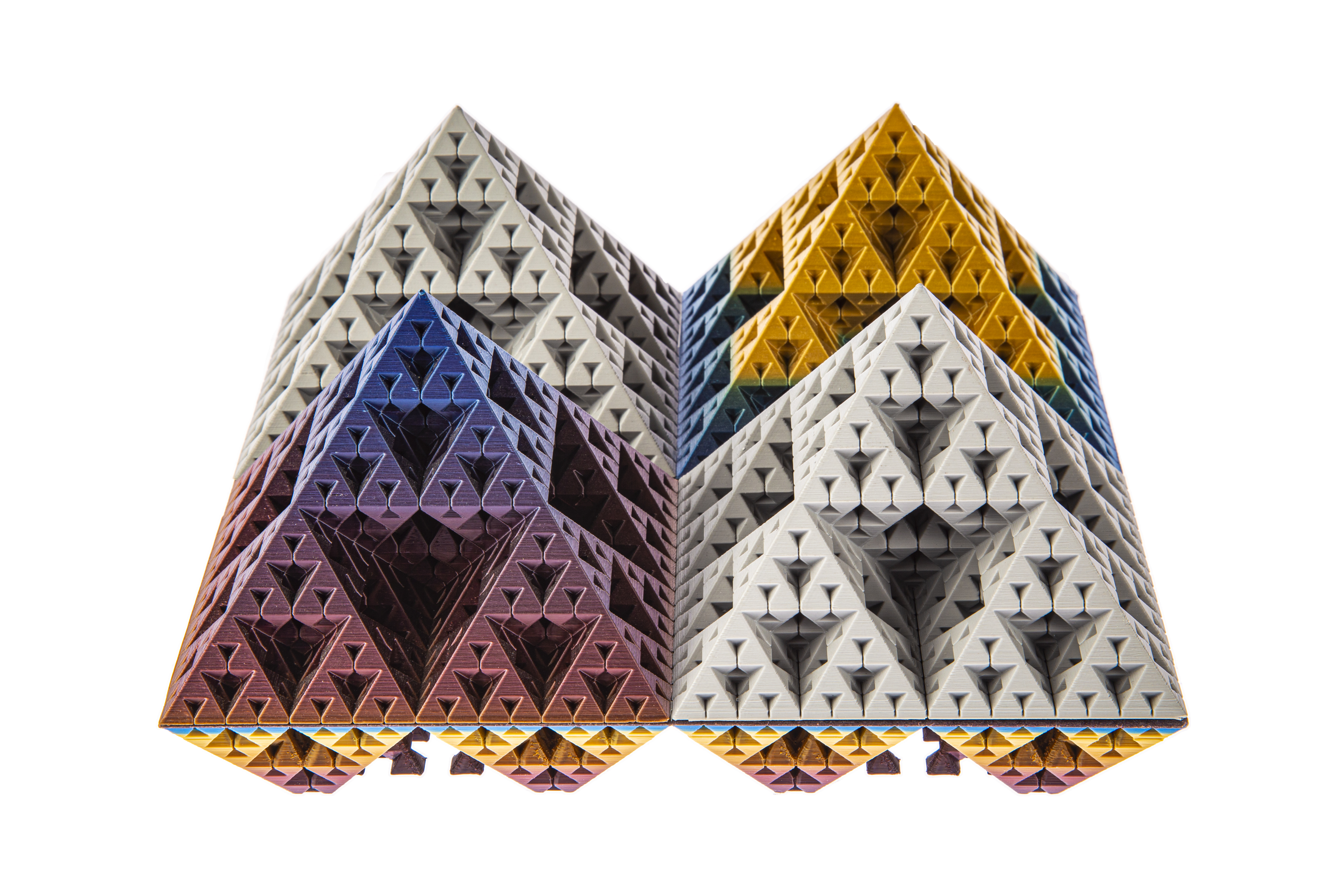

3D printing

Auto leveling that compensates micro-irregularities in the printing surface, for easy and efficient leveling. Filament runout recovery using a sensor that pauses printing when the spool is empty or the filament breaks.

Easy removal of parts thanks to the magnetic flexible print sheet, no more need for a spatula.

The nozzle temperature going up to 275°C and the bed temperature up to 100°C (depending on the version) make it possible to print a wide variety of materials such as PLA, wood PLA, ABS, PETG, TPU95A and many more. others.

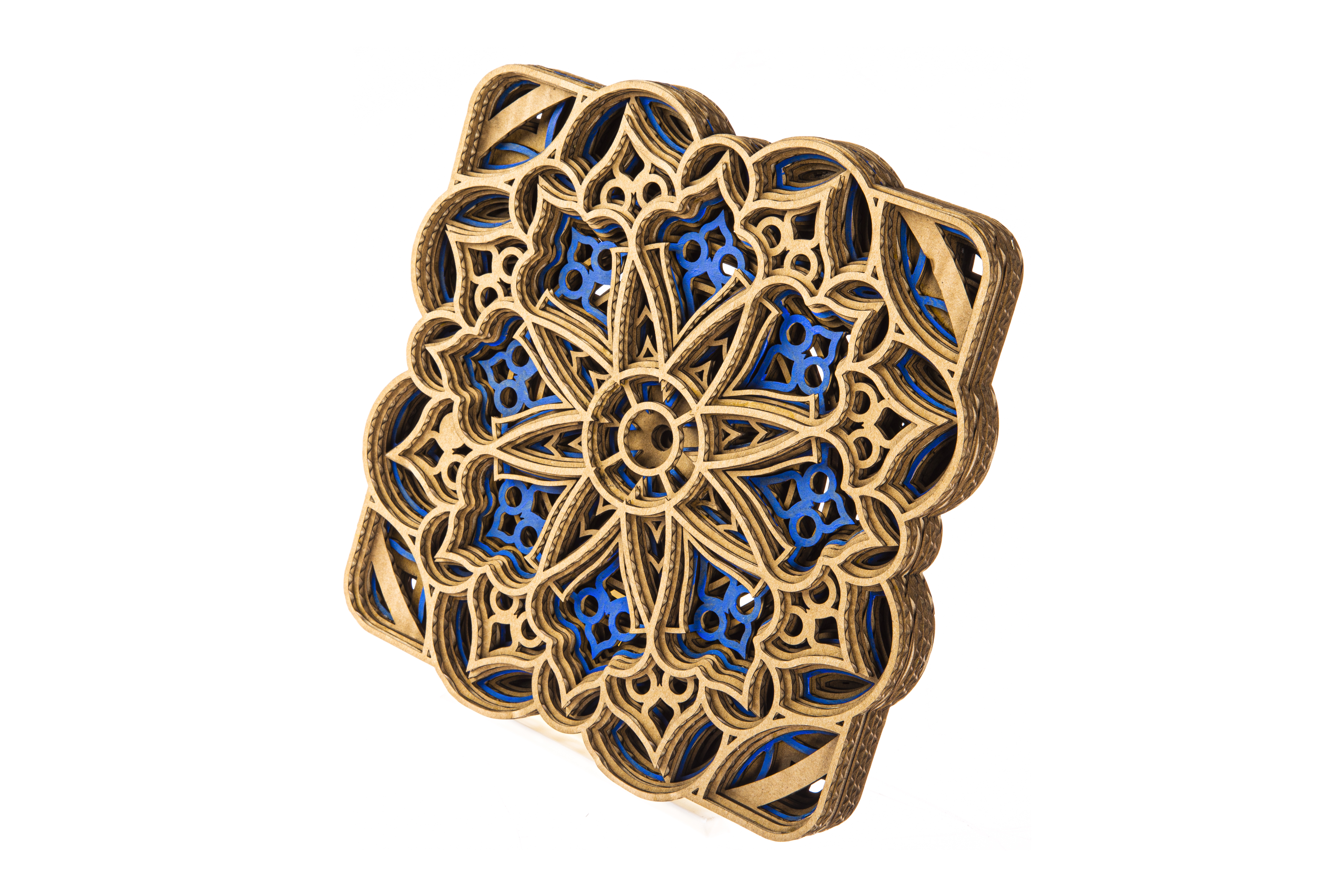

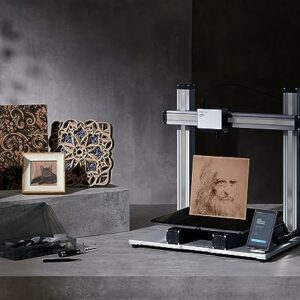

Laser

The 0.2mm x 0.3mm laser point produces high resolution engravings.

The aluminum grid table improve the extraction of fumes and the penetration of the laser point while alleviates burns on the edges of the cuts, particularly on the back of the material.

The laser module allows you to engrave or cut various materials such as plywood, paper, leather, plastic, fabric, acrylic and much more to test.

CNC

More than 100 cutter references are at your fingertips thanks to the tool head compatible with standard ER11 collets that can accommodate shank diameters from 0.5mm to 6.35mm.

Protection of the machine with the MDF martyr and optimal maintenance of the parts with the intelligent material clipping system.

Resistance to dust produced by machining thanks to the enclosing of lead screws, electronic chips and mechanical parts for longer machine life.

Ease of use

The use of the machine is user-friendly thanks to many smart features such as automatic leveling, filament runout sensor or power loss recovery.

5-inch touch screen enables quick access to the various menus and features of the machine. WIFI and USB connectivity to choose the type of connection that best suits your workflow.

The tool heads are quickly and easily changed by the user, the same goes for the build plates.

The Snapmaker Luban software is dedicated and developed for Snapmaker machines and allows you to work with the 3 manufacturing techniques offered by the machine in one same interface. User manual and video tutorials are accessible from the software to make it easier for users to get started.

All-metal design

Built to last, Snapmaker machines incorporate a large number of aluminum alloy parts processed by anodic oxidation for strength and optimal protection.

The high-quality components of the Snapmaker 2.0 make it achieve outstanding precision and durability.

Enclosure

In addition to the practical aspect, the enclosure proves to be an essential element for the safety of users. Its importance is not negligible for organizations giving access to several users to the machine. This is particularly the case for fablabs or educational establishments.

Reduction of the noise and of the laser radiation, isolation of dust, fumes and harmful particles, the enclosure also helps to keep the heat necessary for printing ABS.

For additional security, this enclosure has door opening detection that automatically pauses the work in progress.

A machine according to your needs

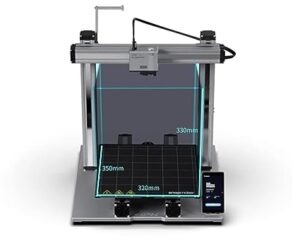

The Snapmaker 2.0 exists in 2 versions: the A350T and the A250T.

The first one has a build volume of 320 x 350 x 330 mm against 230 x 250 x 235mm for the second one. But the smaller one makes it possible to reach a higher bed temperature: 100°C against 80°C for the larger one.

Additionally, Snapmaker machines are customizable. You will be able to put additional modules such as the double print head, a more powerful laser module that can go up to 40W, a rotary module, an air purifier, an emergency stop button,…

FR

FR