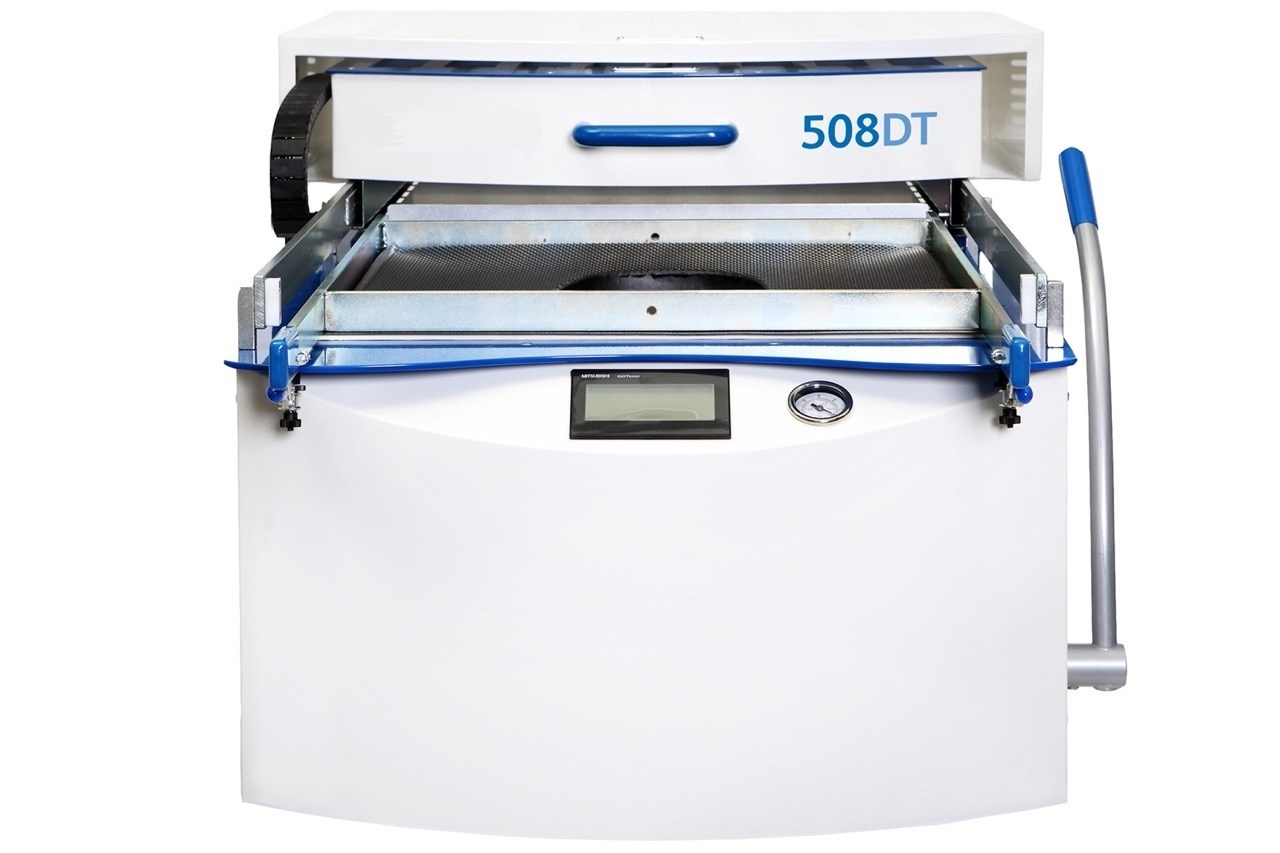

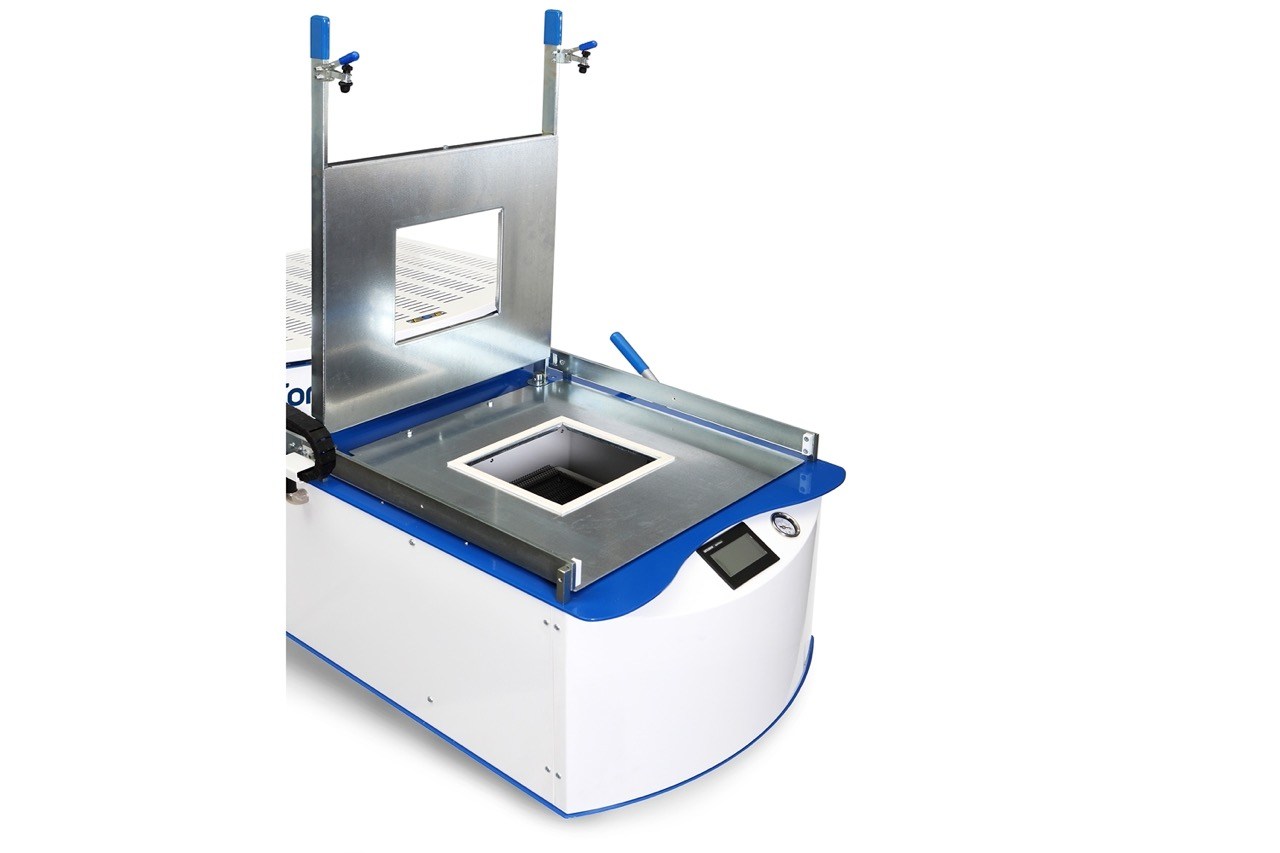

Thermoforming 508DT

The 508DT thermoforming machine enables high-quality forming of complex materials.

It is equipped with a PLC control system. Thanks to its fast and energy-efficient Quartz resistors at variable standby, the 508DT is ready for use in less than five minutes. The machine can store up to 20 thermoforming programs. A custom trolley is available for this machine.

FR

FR