7/05/23

The interaction of gantry machining centers and Sinumerik control systems ensures automated complete machining in large tool manufacturing at Mercedes.

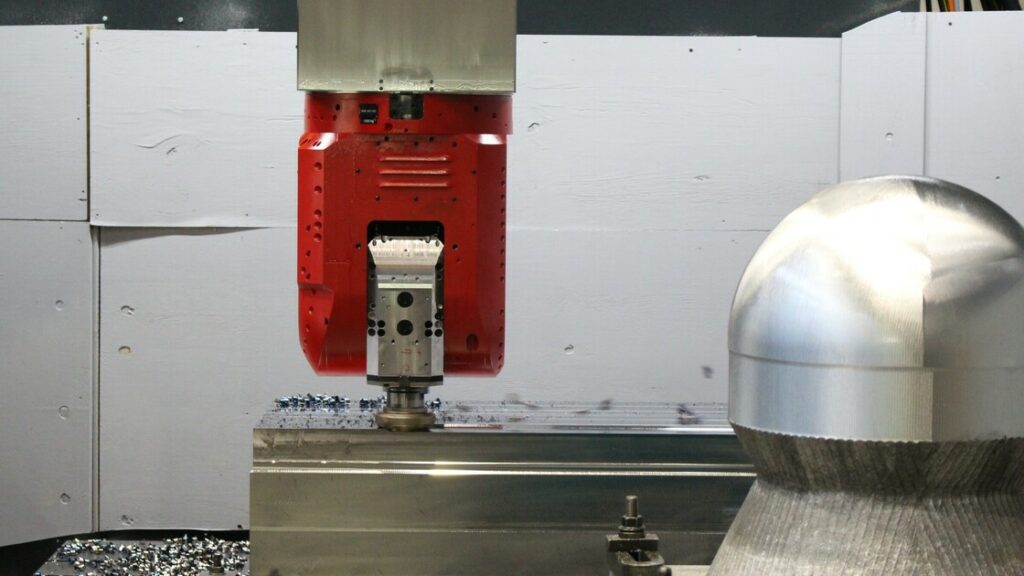

Roughing and finishing combined: The Multi-Contour portal milling machine during milling demonstrations with the GSOC 125 C 500 spindle unit // Picture: Rüdiger Kroh

Automated approach and departure of workpieces with AGVs (Automated Guided Vehicle), integrated roughing and finishing in one machining process – this no longer sounds spectacular for small workpieces and CNC machines. But in large tool manufacturing and with workpieces weighing up to 40 t, it is a groundbreaking process innovation. Automated complete machining was implemented in two automotive factories, on completely hydrostatically guided machine tools from Waldrich Coburg Sinumerik 840D-sl controls.

A yellow AGV navigates driverless and trackless through the large hall of Mercedes-Benz AG. It transports 3,000 mm x 5,500 mm pallets with workpieces weighing up to 40 t between the setup and storage stations and three Waldrich Coburg portal machining centers. Palletizing is automatic, and the changes are controlled by laser scanners. In these workpiece dimensions, this is probably the first automatic, AGV-supported palletizing system of this kind.

View of one of the three portal milling machines at the Sindelfingen factory. The control centers retract and allow the AGVs to enter for automated setup changes // Picture: Siemens

The aim of the system was to achieve a significant step ahead in efficiency and quality in large tool manufacturing. The approach: Where in traditional concepts, roughing or coarse machining and precise surface finishing were previously carried out in separate machines for roughing and finishing, both processes were now to be combined in a single machine for the first time, saving time and optimizing setup. An integration already known from small machining centers. “But in machines for large tool manufacturing, there are extreme requirements,” says Matthias Helmprobst, head of electrical engineering at Waldrich Coburg.

“We are dealing with completely different forces with the high masses and large dynamics. In order to meet the high demands on both process steps – in particular, high cutting performance during roughing and high speeds and dynamics with high precision and surface quality during finishing – spindles with different drive concepts had to be used.”

The driverless transport system moves the blanks weighing up to 40 t between preparation stations, the three portal milling machines and the storage areas // Picture: Siemens

Reliable and accurate machines and controls are needed to meet the accuracy and quality requirements in automotive manufacturing. Added to this was compliance with environmental protection, energy efficiency and ergonomics specifications. Therefore, all project partners had to go innovative ways and develop new machine and control functions. A driverless transport system (AGV) with high safety standards was integrated into the whole package for workpiece transport.

On the machines, press tools are efficiently rough machined and very accurately finished in a single setup. The advantages of hydrostatic guides in combination with finish machining were the largest challenge for Waldrich Coburg and Siemens. With the Multi-Contour series, a powerful and very accurate machine was created. Expectations were thus exceeded in both cases.

With the new driverless transport system, the machines and the nearby set-up and parking areas are safely loaded with the 40 t heavy large workpieces. The AGV also autonomously transports the components within the hall to the assembly teams and back. The transport system can be extended so that process planning and control in the plant can be carried out by a higher-level planning system. In addition, a system from a third manufacturer with nine further pallets was integrated into the workpiece transport system.

To improve damping and accuracy in all machining steps, all linear axes of the Waldrich-Coburg machining centers in the automotive factory are hydrostatically guided. With the damping behavior optimized in this way, factors such as the friction behavior and the freedom from wear of the guides as well as the tool life are improved at the same time. Maintenance costs are reduced and machine availability is increased.

Because the interaction of Sinumerik and hydrostatic guides allows significantly higher dynamic accuracy to be achieved, higher path speeds can be run in the machining steps. This benefits the machining performance of the machine during roughing and finishing. In order to fully exploit their application possibilities without compromising the individual machining processes, the machining centers automatically change not only tools but also the milling heads, namely motor and gear spindle units. Via the changing heads, different machining technologies and strategies can be implemented in one machine.

Matthias Helmprobst, Head of Electrical Engineering at Waldrich Coburg // Picture: WALDRICH COBURG

This machine concept places extreme demands on the control system. First of all, there is the continuous communication between the control system and the AGV. In addition, from the control perspective, each of the machining centers in the factories represents several machines in one. One example is the calculation of tool paths and the optimum dynamics of the various spindle units in the different machining steps.

All this has made the illustration of the machining centers very demanding. Thus, the “Sinumerik M-Dynamics” milling technology package with Top Surface and other options was used. In addition, Siemens Mechatronics Support provided support to optimize the accuracy and speed of axis movements and tool paths in the various application areas via EMC (Engineered Motion Control) and pitch compensation. Overall, together with the machine manufacturer, it was possible to set new standards for the customer in terms of accuracy and machining speed in large tool and mold manufacturing.

Sinumerik and options such as Top Surface also show their strengths in large tool manufacturing. Efficient roughing is immediately followed by very precise finishing with high surface quality. From the pallet change to the finished workpiece, the integrated overall solution from Waldrich Coburg and Siemens convinced the process engineers and factory managers. After the flexible manufacturing system was handed over on schedule, production could be started immediately. 5-sided machining and 3D free-form surface machining are carried out completely on the system.

The special advantages compared to the previous production systems are in particular the further increased precision and faster machining. Due to the excellent manufacturing quality and accuracy, the rework efforts in the tool manufacturing department could be significantly reduced. The introduction of the AGV system also reduced non-productive time. The autonomous parts transport with intelligent order control facilitates the planning and control of orders and enables further efficiency gains in production.

The driverless transport system moves the blanks weighing up to 40 t between preparation stations, the three portal milling machines and the storage areas // Picture: Siemens