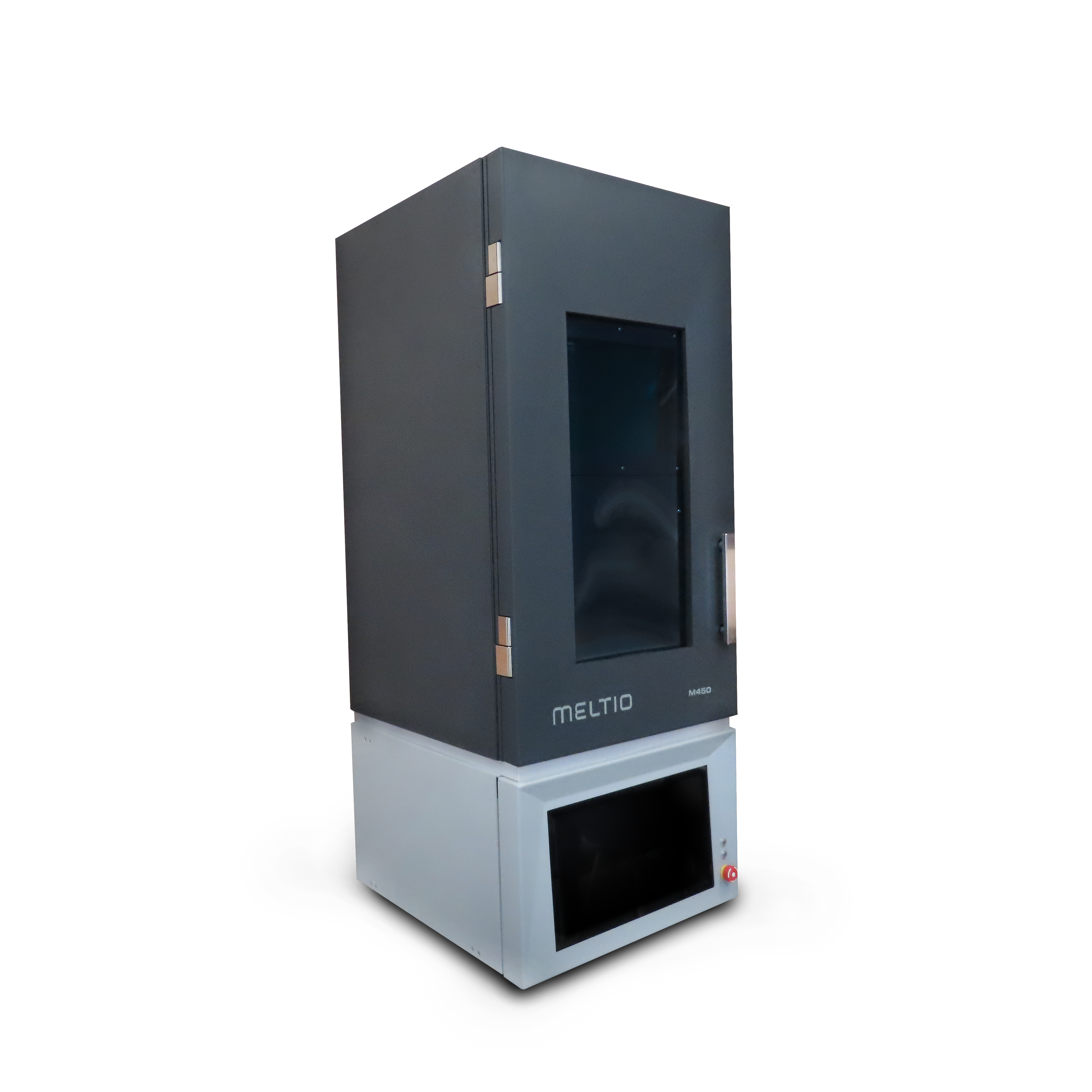

METAL 3D PRINTER M450

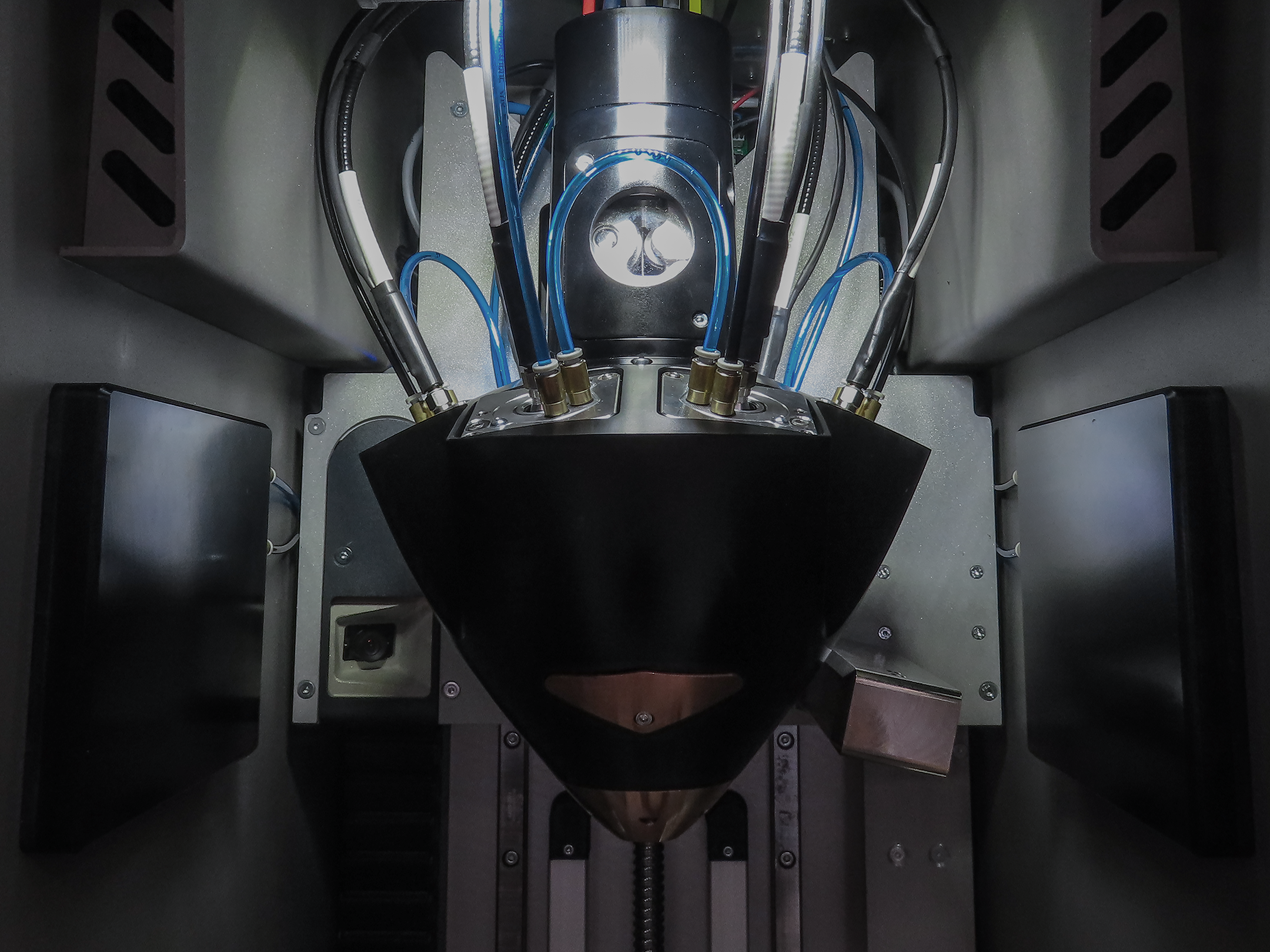

The machine with a patented hybrid head that allows the simplicity of printing with metal wire at a very competitive price.

Unique technology

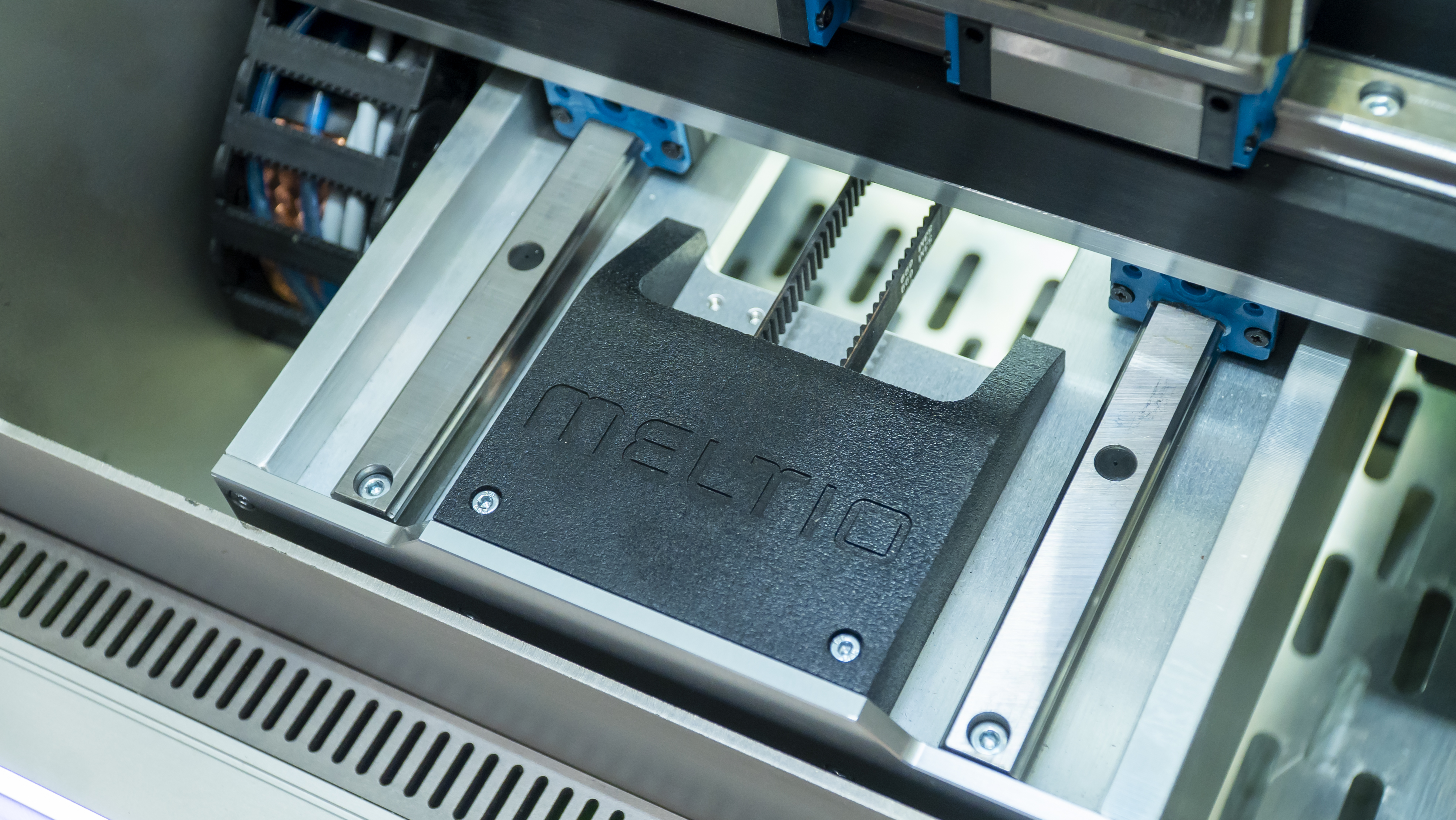

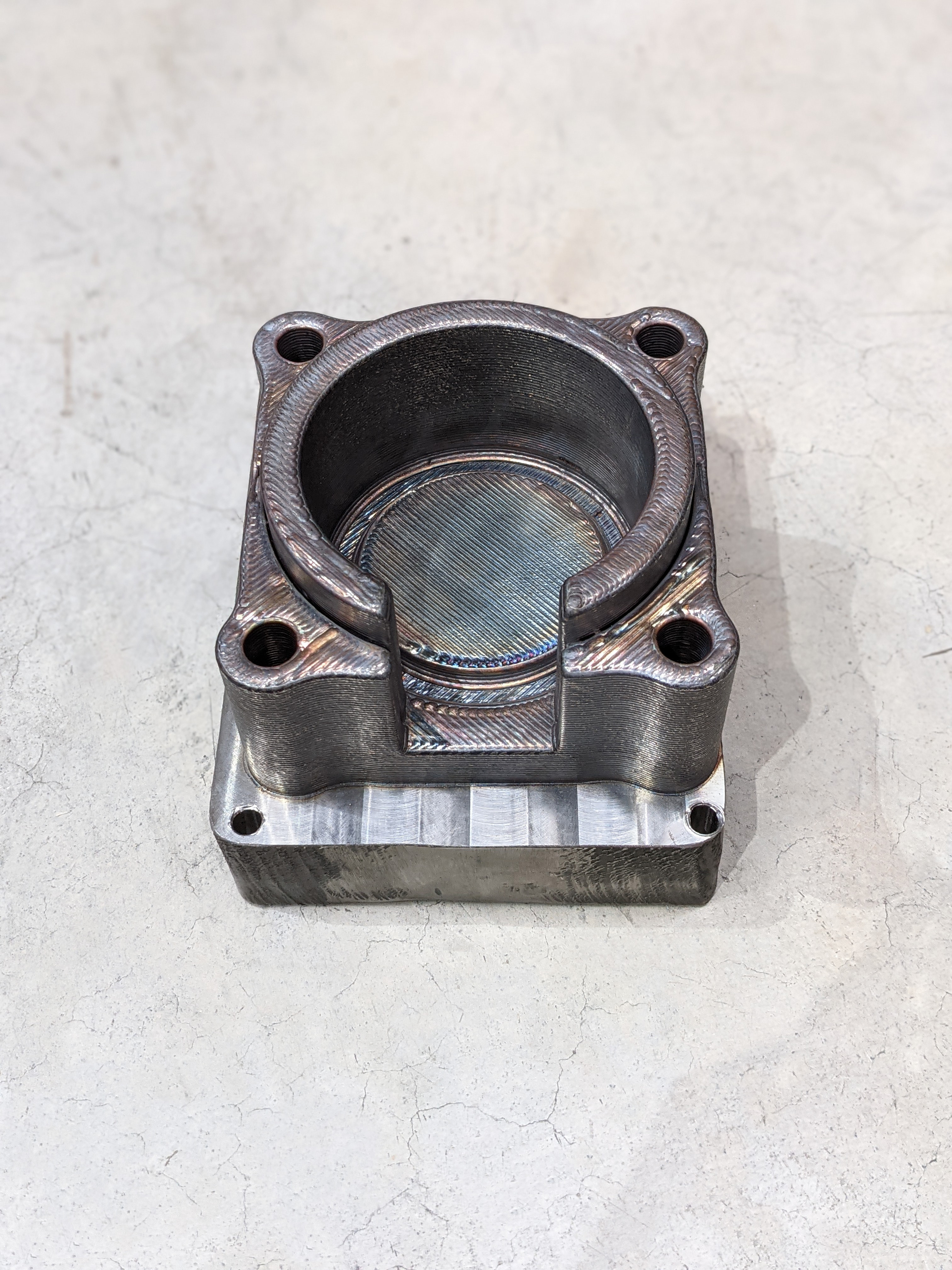

Meltio M450 can produce complexe metallic components from wire feedstock. The ability to produce parts from wires makes operation and material handling very clean, as well as ensuring 100% material efficiency.

Low-cost entry solution for professional Metal 3D printing

M450 provides a low-cost entry to metal additive manufacturing. It can use any commercially available metal wires in the market and the cost of both the equipment and the spare parts is substantially lower compared to competing technologies.

Amazing build envelope in a compact format

Despite its compact outer dimensions Meltio M450 features o significant print envelope of 150 x 170 x 450 mm3. The printer is clean and safe, without the typical hassle of common and bulky industrial hardware.

Great results and versatility

Its sealed atmosphere eliminates oxidation, enabling 3D printing of reactive metals. M450 features not only metal 3D printing of full parts, but also an all-in-one additive manufacturing solution for repairing parts, laser cladding, laser welding (autogenous and with filler), laser cutting, laser texturing and polishing.

Easy to use software

The printer features a powerful on-board computer with 17” touchscreen and a feature rich GUI with advanced custom designed software to allow easy model slicing and access to process parameters. The printer can also be controlled via a tablet or computer through a local wireless network or via an Ethernet connection.

FR

FR

Patented Multi-Laser Head Design

Patented Multi-Laser Head Design