6/09/22

Linares, Spain – September 6th, 2022.

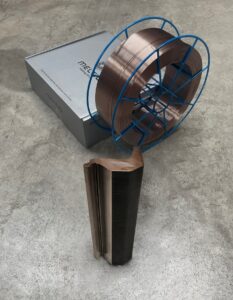

Meltio; a disruptive laser metal deposition technology manufacturer, announced today that it is launching four new materials as part of its own metal wire materials range. However, the Meltio products will maintain their open materials platform option to accentuate the importance of materials as a key factor in the 3D printing user experience.

The Meltio Materials range consists of materials that are extensively tested under controlled conditions with validated part properties and out-of-the-box optimized print parameters. The second batch of welding wires includes Stainless Steel 17-4PH, Tool Steel H11, Nickel 625, and Invar. Earlier this year, the company launched the first batch, consisting of Stainless Steel 316L, Stainless Steel 308L, Mild Steel ER70S, Titanium 64, and Nickel 718.

Expanding the Meltio Materials range with these four specific metals allows to dive deeper into the realm of materials, and provide parametrized welding wires for a wide range of applications as well as a few niche ones. The new materials continue ensuring the same first-time-right experience just like the first batch, with guaranteed part properties, and optimized print profiles. Furthermore, Meltio’s aim with the extended range is to cater to a broad audience, regardless of their previous experience with welding or metal additive manufacturing.

Meltio’s wire LMD technology remains compatible with third-party commodity welding wire. Currently, Meltio’s pioneering process is compatible with most stainless steels, mild steels, tool steels, titanium alloys, nickel alloys, and invar. In addition, precious metals like gold have been showing great results in customer-led projects. Materials like copper, aluminum, and refractories continue to be under development.

By offering the Meltio Materials range as well as maintaining an open materials platform, Meltio users benefit from the best of both worlds. On the one hand, it has the added value of first-time-right with the Meltio Materials’ optimized print profiles. On the other hand, the open materials platform provides the Meltio users with an option to push the envelope by experimenting with different materials.

Meltio takes metal additive manufacturing to the next level by developing high-performance, affordable, and easy-to-use metal 3D printing solutions using wire LMD technology.

The company’s mission is to delight customers, partners and employees by pioneering the development of affordable metal 3D printing systems that are reliable, safe, and powerful, continually reinforcing their status as disruptors.

Media contact : Júlia Hencz – Meltio Digital Communications Specialist