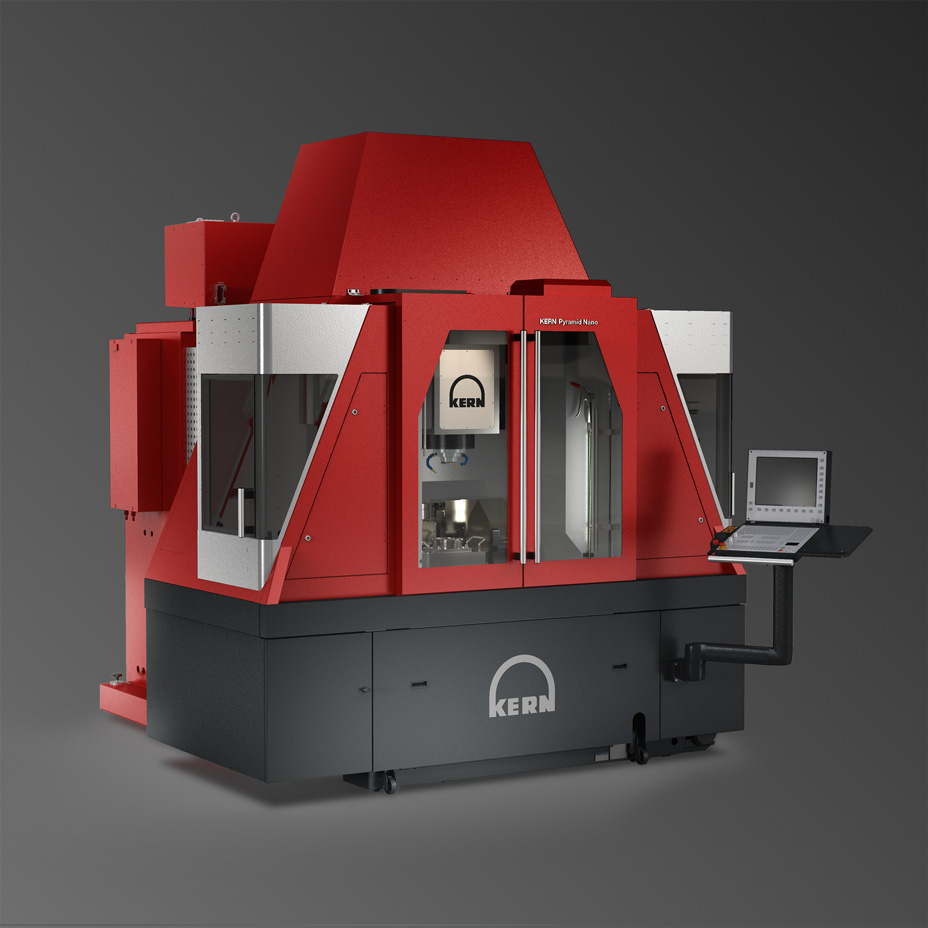

Perfection in every dimension

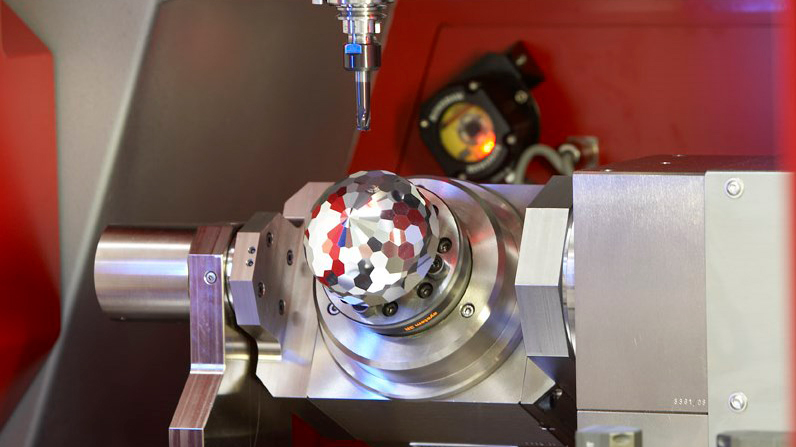

Hydrostatic milling and grinding

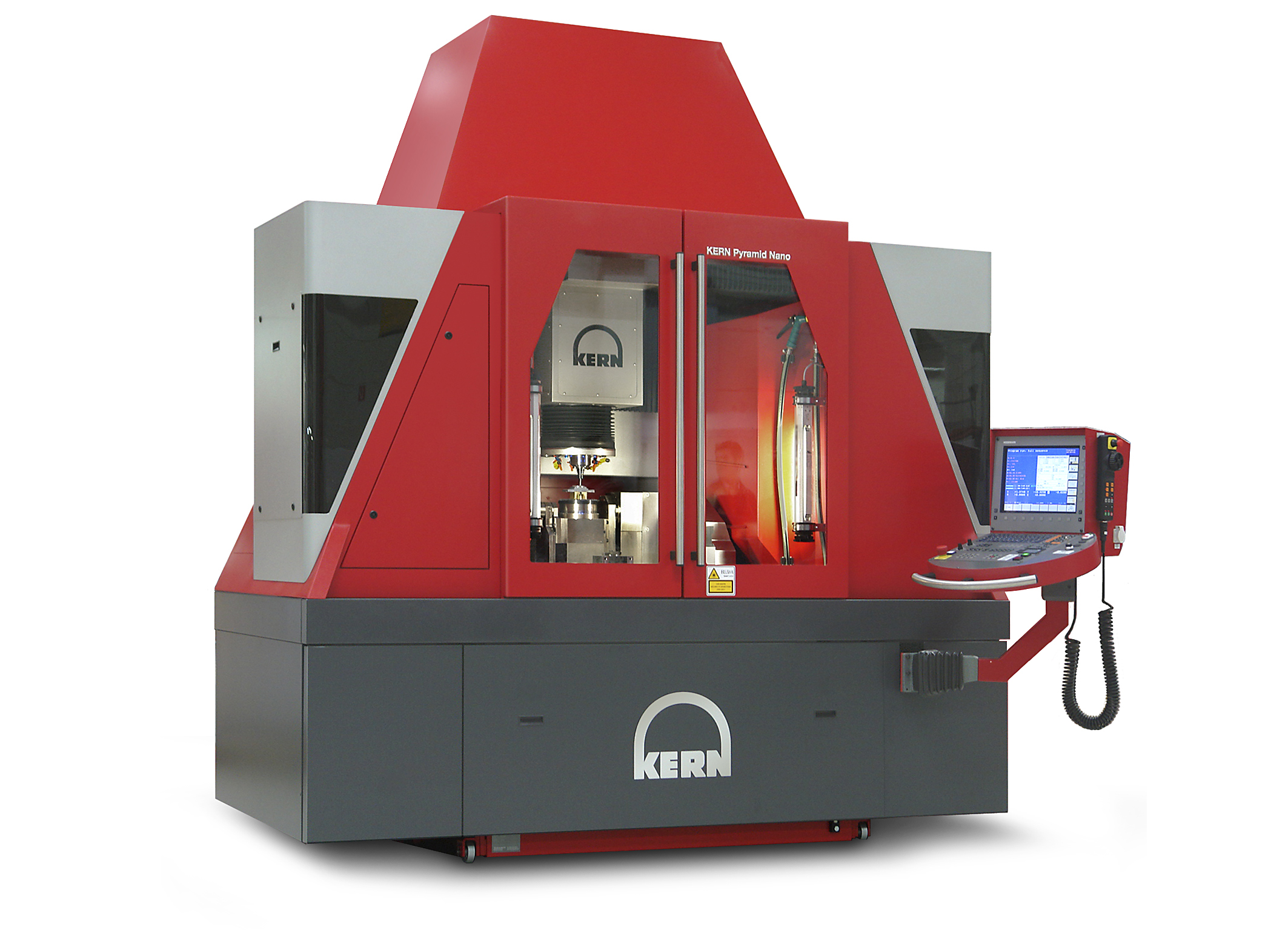

Whether with 3 or 5 axes mounted on and driven by hydrostatic bearings, KERN Pyramid Nano is one of the most precise CNC machining centers in the world. By focusing on reliability in serial operation, this machine achieves ultra-precision manufacturing of industrial workloads.

Maximum precision and stability over long time-frames.

Thanks to its hydrostatic drives and guides, the machine suffers virtually no wear in its linear axes. This means the quality and precision of all axes remain constant over extremely long time-frames. In conjunction with KERN’s proprietary thermal management system, you have a perfectly optimized tool at any time.

Features and benefits at a glance

Maximum productivity and precision

The proverbial KERN precision not only includes ultraprecise machining in the micrometer range, but also optimum repeatability with maximum productivity from the first part.

The design concept of the KERN Pyramid Nano aims to push the limits of feasibility and ensure maximum precision on the workpiece during series production.

Life-long precision

By combining an intelligent machine structure and gantry design with premium components and hydrostatic drives and bearings, KERN has ensured that the machine will retain optimum accuracy throughout its lifetime. Maximum precision, an absence of wear and series stability over prolonged periods are thus the fundamental qualities of the KERN Pyramid Nano.

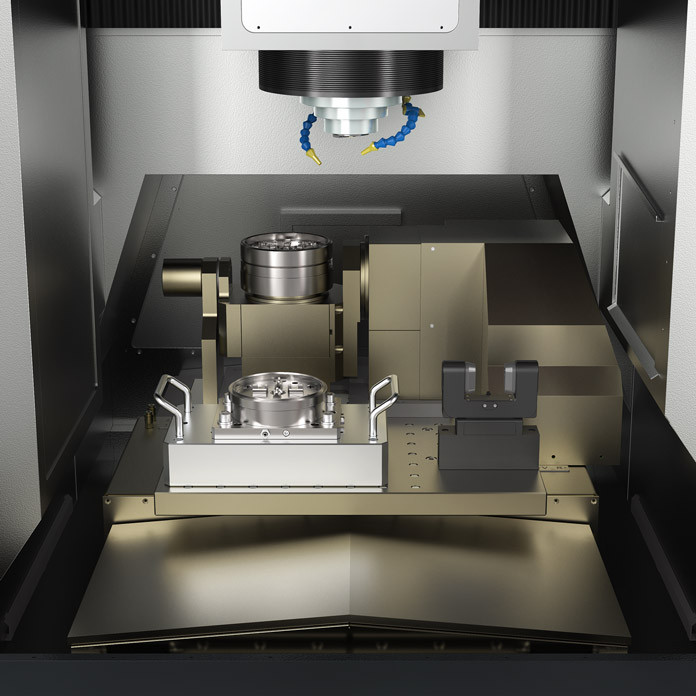

Optimized for every application

The KERN Pyramid Nano can be perfectly adapted to your requirements and applications thanks to a comprehensive range of equipment levels, modules and accessories. The fully integrated jig grinding package enables the KERN Pyramid Nano to be used for a wide range of diverse applications.

Even after delivery, we are ready to support you with process creation and production optimization.

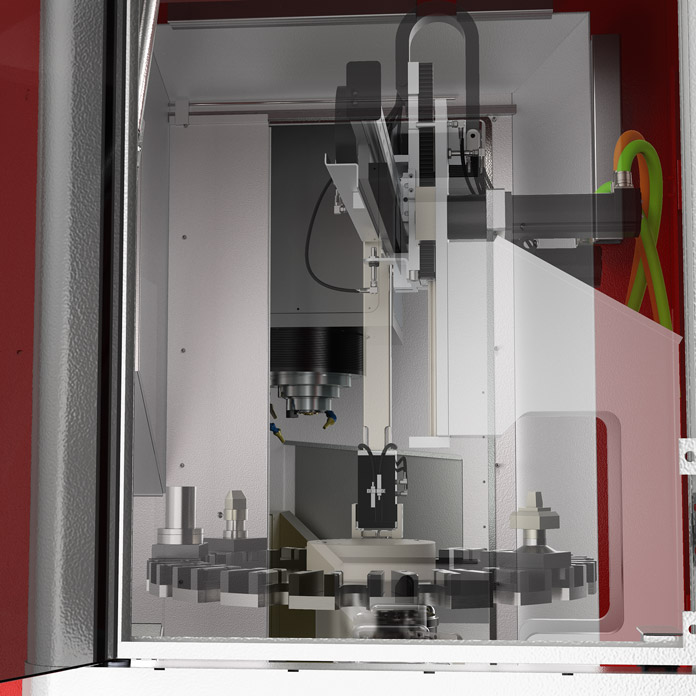

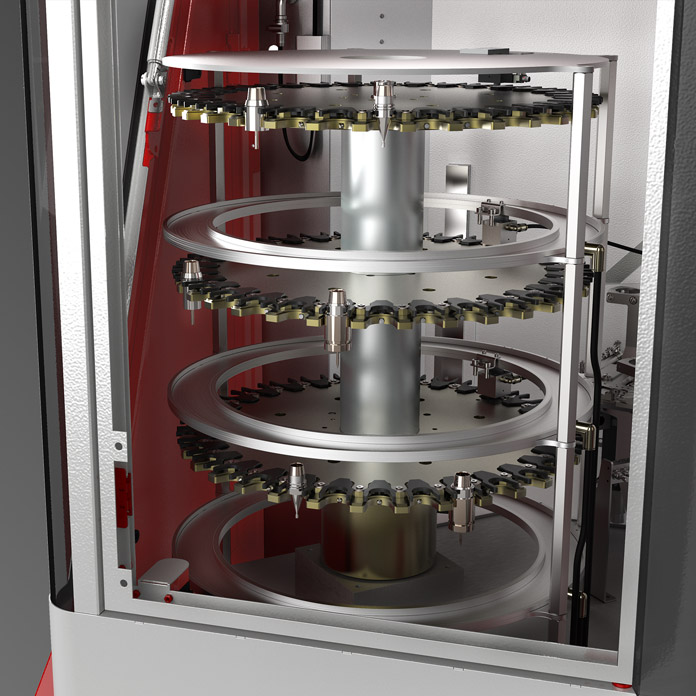

Automation and productivity

In addition to an internal tool changing system, the KERN Pyramid Nano also includes an integrated workpiece robot with workpiece magazine, making it optimally designed for unmanned operation. External workpiece loading systems can be integrated seamlessly into the machine and optimized

for your specific application.

FR

FR