Multistation equips education players with digital and additive manufacturing solutions: range of digitally-controlled manufacturing equipment for education, FAB LAB, designers…

Multistation, a pioneer in rapid prototyping for over 30 years, is the prime contractor for your FAB LAB, your digital manufacturing and prototyping workshop.

We offer various scalable turnkey formulas, and are able to supply a variety of machines for your FAB LAB, such as laser or waterjet cutting, desktop digital lathes and milling machines, 3D printers and scanners, vacuum casting, etc.

Multistation in a nutshell:

The FDM process consists of extruding and depositing successive layers of molten material to create three-dimensional objects.

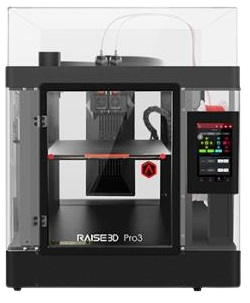

Raise3D produces large-format 3D printers featuring a large, high-definition touch screen and other practical features to facilitate day-to-day use, adjustments and maintenance operations.

RAISE3D – Pro3

Zortrax is a renowned company in the field of 3D printing, offering high-quality printers and materials, enabling professionals to create prototypes and functional parts with great precision.

ZORTRAX – M300 Dual

Flashforge supplies high quality, value-for-money 3D printers for all kinds of users.

Yeti Tool is a British company that designs and manufactures intelligent tools for workshops and construction sites. The Smartbench is a compact and versatile CNC milling machine that is easy to move around, offering precise cutting, engraving, sculpting and tracing capabilities for a wide variety of materials.

3Devo systems recycle plastic waste by developing new ranges of filaments, offering a complete solution for creating 3D objects with great flexibility and efficiency.

3DEVO – Precision 350

This solution heats and molds plastic sheets to create packaging, industrial parts and prototypes with precision and speed, offering an efficient solution for mass production and prototyping.

FORMECH – 450 DT

A wide range of vacuum casting machines, from the CSV-Mini for small parts to the CSV-1500 with a 1200 x 1600 x 1000 mm casting chamber for series production.

Lasercut uses a cutting technique based on a high-precision laser to cut and engrave various materials such as wood, acrylic, paper and metal. This enables complex cut-outs, detailed patterns and customized engravings to be produced with great precision and a high-quality finish.

LASERCUT – LASERCUT 2

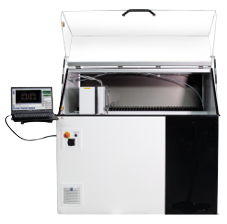

Multi-Waterjet is a leader in the field of waterjet cutting. Their expertise and cutting-edge technology enable precise, versatile cutting in a wide range of materials. With Multi Waterjet, you can achieve superior results for your manufacturing and design projects.

MULTI-WATERJET

Bofa is a specialist manufacturer of fume and particulate extraction systems for industrial applications. Their reliable and efficient extraction solutions ensure a safe working environment by eliminating harmful fumes and particles generated during processes such as laser cutting, welding and 3D printing.

BOFA – 3D Print Pro3

3D LAB atomizers are powered by ATO technology, which uses ultrasonic vibrations to transform molten metal into metal powder under inert gas. The size of the powder depends on the ultrasonic frequency used. The process involves melting the raw material under pressure, ejecting droplets of metal using ultrasound, then cooling them in a stream of argon gas to obtain spherical particles.

3D LAB – ATO Lab +

Scantech specializes in 3D scanning solutions. Their highly accurate 3D scanners precisely capture object geometry, enabling the creation of detailed digital models for a variety of applications such as reverse engineering, quality control and 3D modeling.

SCANTECH – iReal 2E

Shining 3D is a leading player in the field of 3D scanners. Their highly accurate 3D scanners precisely capture object geometry, offering high-quality 3D scanning solutions for a variety of applications such as engineering, architecture and design.

SHINING 3D – EinScan HX

A 3D printer filament is a thread-like material used as a raw material in the FDM 3D printing process. It is generally a thermoplastic material that is heated and extruded by the 3D printer’s extruder to create successive layers and form a 3D object. Filaments are available in a variety of colors and physical properties to meet the specific needs of 3D printing projects

Bigrep is a world leader in industrial 3D printing, offering solutions tailored to the specific needs of research centers. By combining large-scale printing, material versatility, enhanced reliability and user-friendly software tools, Bigrep offers research centers the means to realize ambitious projects and push back the frontiers of innovation through 3D printing.

Meltio specializes in metal additive manufacturing technologies. Their advanced solutions use the wire laser process, which consists of a laser fusing a metal wire. Meltio offers research centers advanced metal 3D printing solutions that foster innovation and flexibility, opening up new perspectives for research and development in the field of metal additive manufacturing.

Admatec specializes in ceramic additive manufacturing. Their 3D printers use digital projection lithography (DLP) technology to create high-precision ceramic parts. For research centers, Admatec offers several significant advantages. Their systems can produce complex parts with high resolution and excellent surface quality, opening up new possibilities for research in the fields of biotechnology, electronics, aerospace and more.

Our team of application engineers is at your disposal for any additional technical or commercial information, such as POC, benchmarks or pre-series.

multistation@multistation.com

02 99 15 35 35

Read more :